Nissan Juke Service and Repair Manual : Rear suspension assembly

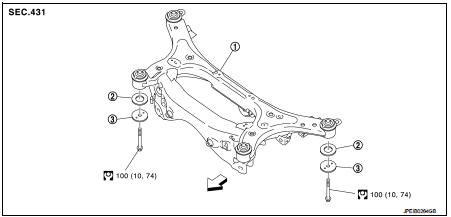

Exploded View

1. Rear suspension member

2. Rebound stopper

3. Washer

: Vehicle front

: Vehicle front

N·m (kg-m, ft-lb)

N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Remove center pipe. Refer to EX-6, "Removal and Installation".

3. Remove propeller shaft. Refer to DLN-121, "Removal and Installation".

4. Remove stabilizer bar. Refer to RSU-34, "Removal and Installation".

5. Remove wheel sensor and sensor harness. Refer to BRC-86, "REAR WHEEL SENSOR : Removal and Installation" (Without ESP), BRC-227, "REAR WHEEL SENSOR : Removal and Installation" (With ESP).

6. Remove upper link from suspension arm. Refer to RSU-32, "Removal and Installation".

7. Remove lower link from suspension arm. Refer to RSU-30, "Removal and Installation".

8. Remove drive shaft from rear final drive. Refer to RAX-17, "Removal and Installation".

9. Remove rear final drive. Refer to DLN-144, "Removal and Installation".

10. Set jack under rear suspension member.

CAUTION:

• Never damage the suspension member with a jack.

• Check the stable condition when using a jack.

11. Remove rear suspension member mounting bolts, rebound stopper, and washer.

12. Slowly lower jack, then remove rear suspension member, lower link and upper link from vehicle as a unit.

CAUTION:

Operate while checking that jack supporting status is stable.

13. Remove lower link and upper link from rear suspension member.

14. Perform inspection after removal. Refer to RSU-36, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of the removal.

• To install mounting bolts of the suspension member, temporarily tighten them in numerical order shown in the figure and tighten them to the specified torque.

: Vehicle front

• Perform the final tightening of each parts removed when removing rear suspension assembly under unladen conditions.

• Perform inspection after installation. Refer to RSU-36, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check rear suspension member for deformation, cracks, or any other damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer toBRC-85, "REAR WHEEL SENSOR : Exploded View" (Without ESP), BRC-225, "REAR WHEEL SENSOR : Exploded View" (With ESP).

2. Check wheel alignment. Refer to RSU-20, "Inspection".

3. Adjust neutral position of steering angle sensor. Refer to BRC-149, "Work Procedure" (With ESP).

Rear stabilizer

Rear stabilizer

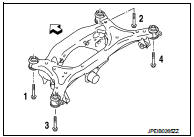

Exploded View

1. Stabilizer bar

2. Bushing

3. Stabilizer clamp

4. Stabilizer link

5. Lower link

6. Rear suspension member

: Vehicle front

: Always replace after every

disassembly.

: N ...

Other materials:

Moonroof (if so equipped)

WARNING

• In an accident you could be thrown from the vehicle through an open moonroof.

Always use seat belts and child restraints.

• Do not allow anyone to stand up or extend any portion of their body out of the

moonroof opening while the vehicle is in motion or while the moonroof is closing. ...

Diagnosis system (BCM)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...