Nissan Juke Service and Repair Manual : Ecu diagnosis information

TCM

Reference Value

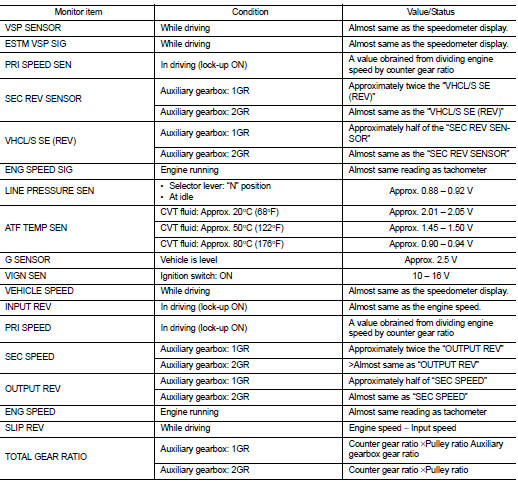

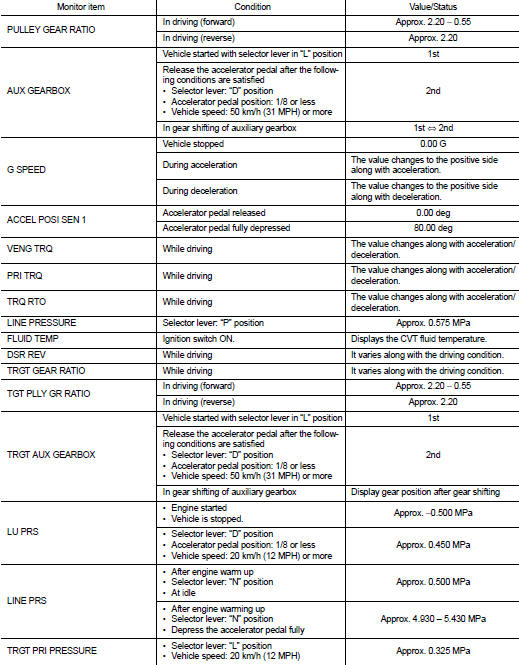

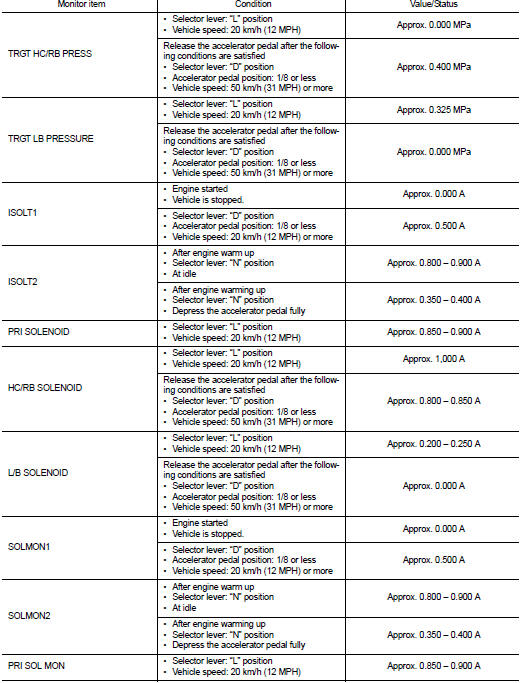

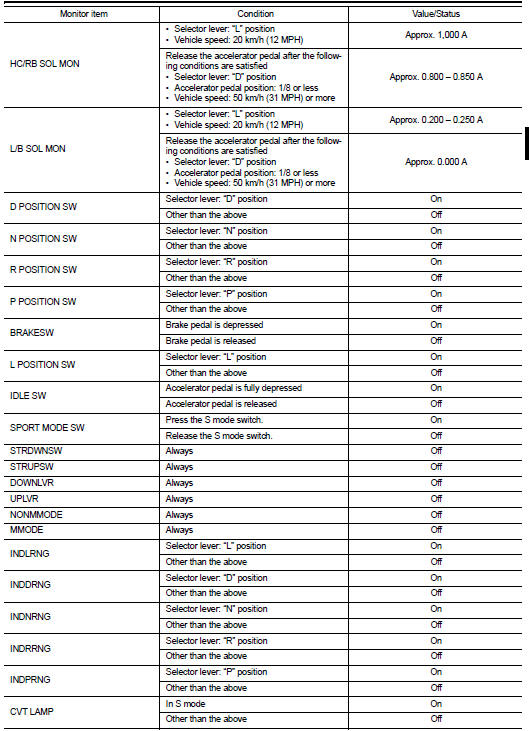

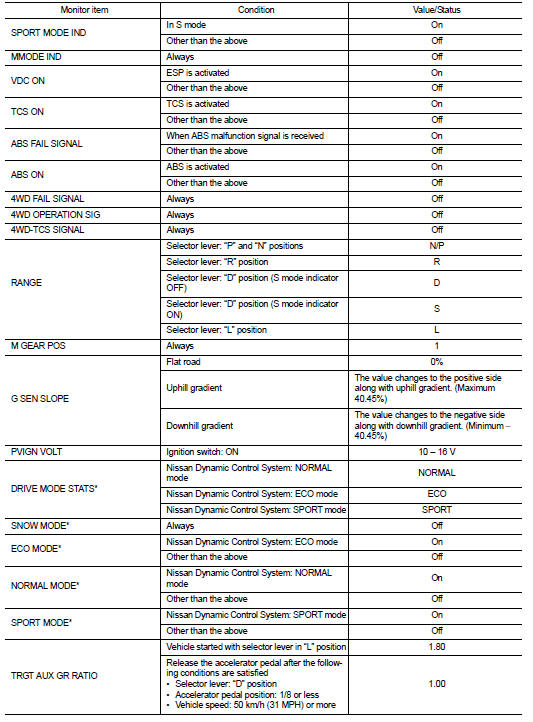

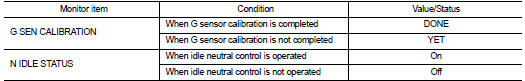

CONSULT-III DATA MONITOR STANDARD VALUE

• In CONSULT-III, electric shift timing or lock-up timing, i.e. operation timing of each solenoid valve, is displayed.

Therefore, if there is an obvious difference between the shift timing estimated from a shift shock (or engine speed variations) and that shown on the CONSULT-III, the mechanism parts (including the hydraulic circuit) excluding the solenoids and sensors may be malfunctioning. In this case, check the mechanical parts following the appropriate diagnosis procedure.

• Shift point (gear position) displayed on CONSULT-III slightly differs from shift pattern described in Service Manual. This is due to the following reasons.

- Actual shift pattern may vary slightly within specified tolerances.

- While shift pattern described in Service Manual indicates start of each shift, CONSULT-III shows gear position at end of shift.

- The solenoid display (ON/OFF) on CONSULT-III is changed at the start of gear shifting. In contrast, the gear position display is changed at the time when gear shifting calculated in the control unit is completed.

*: With Nissan Dynamic Control System

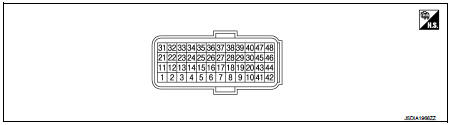

TERMINAL LAYOUT

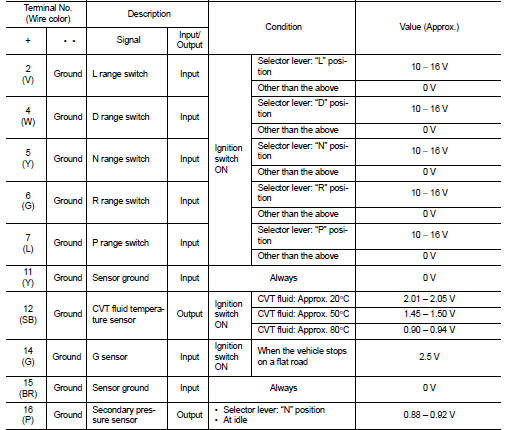

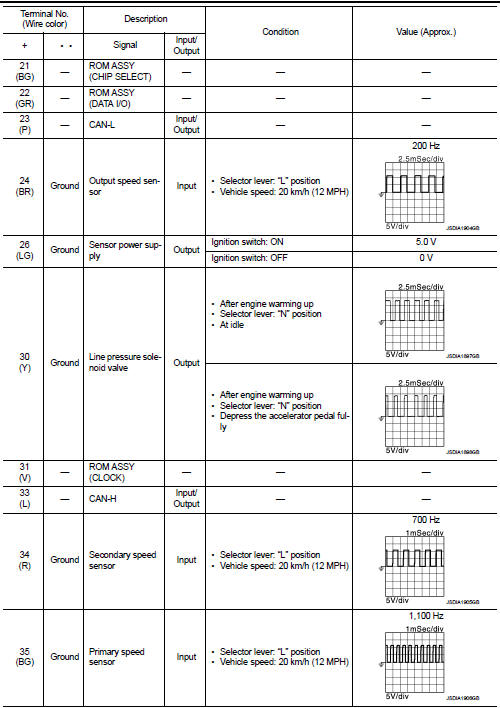

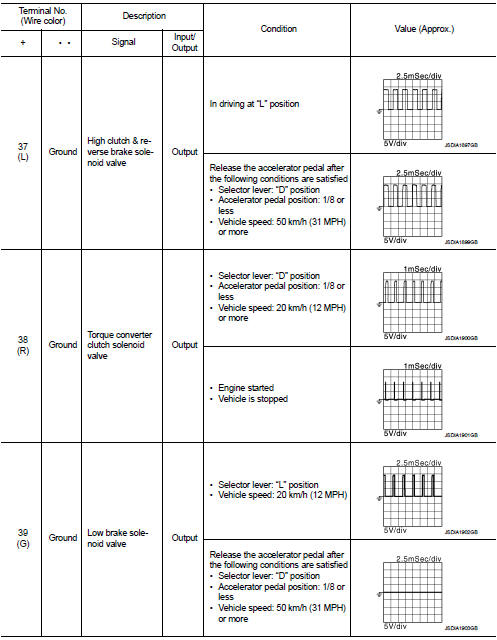

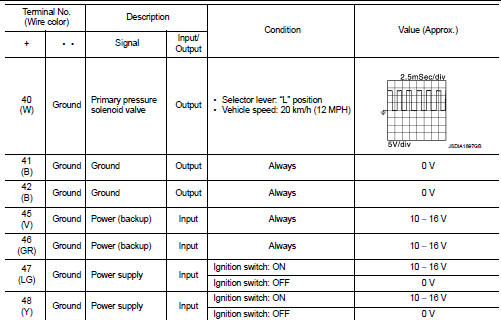

INPUT/OUTPUT SIGNAL STANDARD

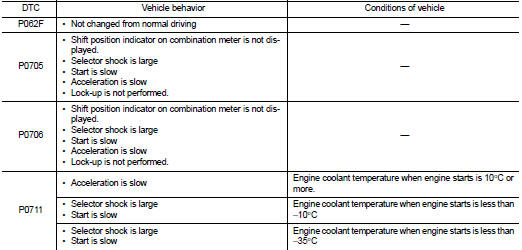

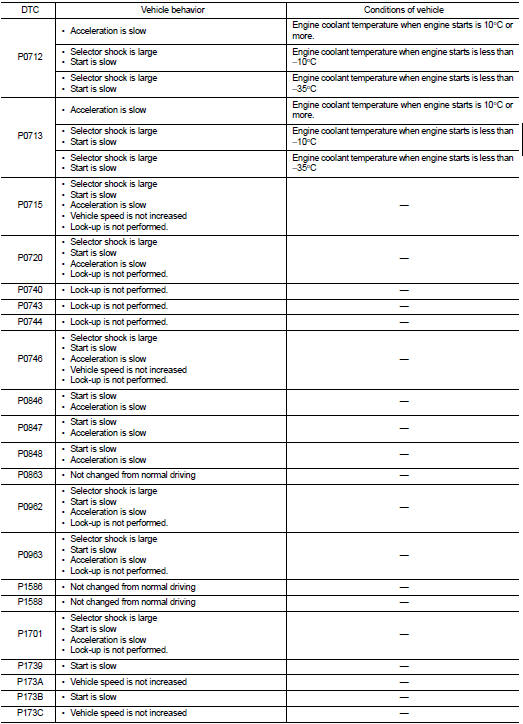

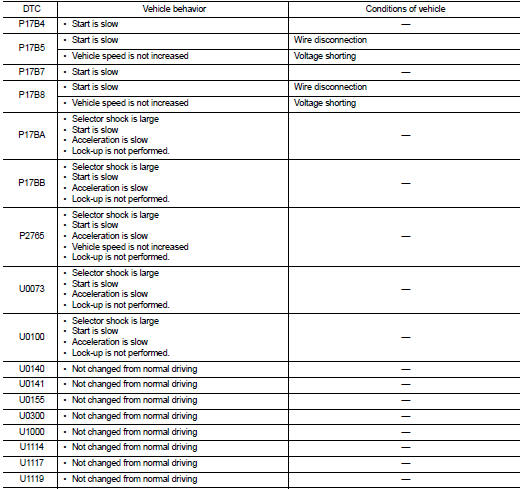

Fail-Safe

TCM has a fail-safe mode. The mode functions so that operation can be continued even if the signal circuit of the main electronically controlled input/output parts is damaged.

If the vehicle shows following behaviors including "poor acceleration", a malfunction of the applicable system is detected by TCM and the vehicle may be in a fail-safe mode. At this time, check the DTC code and perform inspection and repair according to the malfunction diagnosis procedures.

Fail-safe function

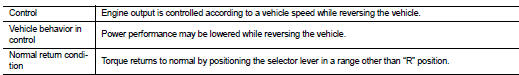

Protection control

The TCM becomes the protection control status temporarily to protect the safety when the safety of TCM and transmission is lost. It automatically returns to the normal status if the safety is secured.

The TCM has the following protection control.

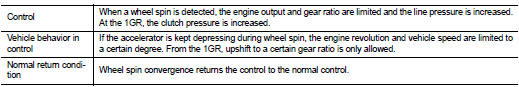

CONTROL FOR WHEEL SPIN

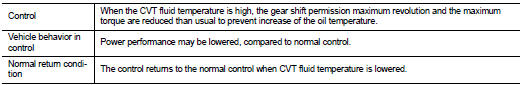

CONTROL WHEN FLUID TEMPERATURE IS HIG

TORQUE IS REDUCED WHEN DRIVING WITH THE REVERSE GEAR

REVERSE PROHIBIT CONTRO

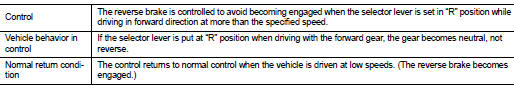

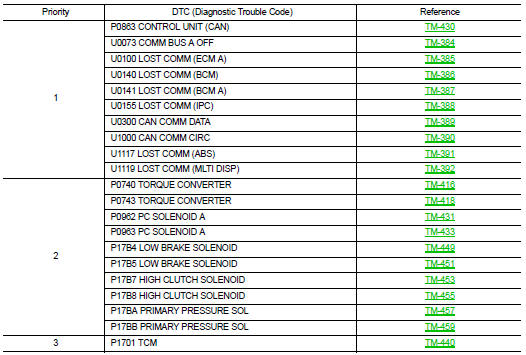

DTC Inspection Priority Chart

If multiple malfunction codes are detected at the same time, check each code according to the DTC check priority list below.

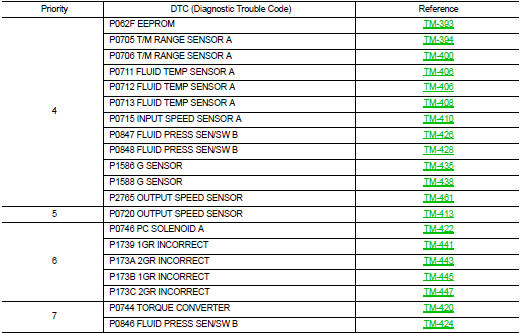

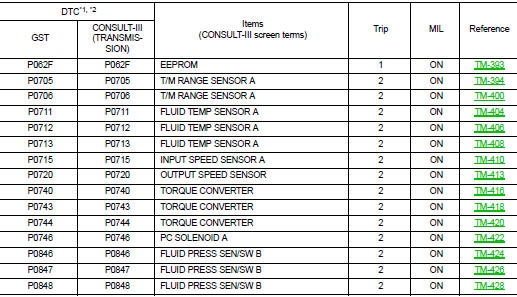

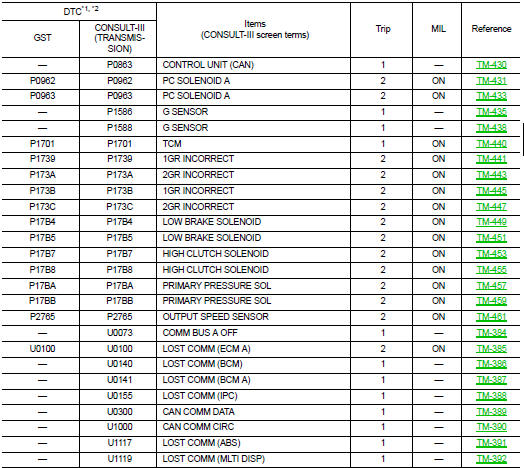

DTC Index

NOTE

:

• If multiple malfunction codes are detected at the same time, check each code

according to the "DTC check

priority list". TM-365, "DTC Inspection Priority Chart".

• The ignition counter is displayed in “FFD”. Refer to TM-347, "CONSULT-III Function (TRANSMISSION)".

*1: These numbers are specified by SAE J2012/ISO 15031-6.

*2: The DTC number of the 1st trip is the same as the DTC number.

Diagnosis system (TCM)

Diagnosis system (TCM)

Diagnosis description : 1 Trip Detection Diagnosis and 2 Trip Detection

Diagnosis

NOTE:

“Start the engine and turn OFF the ignition switch after warm-up.” This is

defined as 1 trip.

1 TRIP DE ...

Wiring diagram

Wiring diagram

...

Other materials:

Vehicle Dynamic Control (VDC) off switch

The vehicle should be driven with the Vehicle Dynamic Control (VDC) system on

for most driving conditions.

If the vehicle is stuck in mud or snow, the VDC system reduces the engine output

to reduce wheel spin. The engine speed will be reduced even if the accelerator is

depressed to the floo ...

C1140 actuator relay system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

P1610 lock mode

Description

ECM forcibly switches to the mode that inhibits engine start, when engine

start operation is performed 5 times

or more while communication between ECM and BCM is not normal, or when engine

start operation is performed

5 times or more using the unregistered ignition key.

DTC Logic ...