Nissan Juke Service and Repair Manual : Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

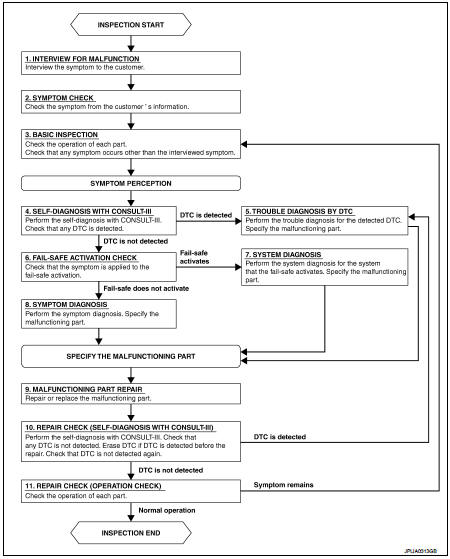

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation of each part. Check that any symptom occurs other than the interviewed symptom.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT-III

Perform the self-diagnosis with CONSULT-III. Check that any DTC is detected.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 9.

6.FAIL-SAFE ACTIVATION CHECK

Check that the symptom is applied to the fail-safe activation.

Does the fail-safe activate? YES >> GO TO 7.

NO >> GO TO 8.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system that the fail-safe activates. Specify the malfunctioning part.

>> GO TO 9.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Specify the malfunctioning part.

>> GO TO 9.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 10.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT-III)

Perform the self-diagnosis with CONSULT-III. Check that any DTC is not detected. Erase DTC if DTC is detected before the repair. Check that DTC is not detected again.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 11.

11.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> INSPECTION END

NO >> GO TO 3.

Ecu diagnosis information

Ecu diagnosis information

BCM, IPDM E/R

List of ECU Reference

...

Other materials:

EGR volume control valve closed position learning

Description

EGR Volume Control Valve Closed Position Learning is an operation to learn

the fully closed position of the

EGR volume control valve by monitoring the EGR volume control valve control

position sensor output signal.

Work Procedure

1.START

1. Turn ignition switch ON.

2. Perform ? ...

Headlamp aiming system (manual)

Component Inspection

1.CHECK HEADLAMP AIMING SWITCH

1. Remove headlamp aiming switch.

2. Check resistance among each headlamp aiming switch terminal.

Is the inspection result normal?

YES >> Headlamp aiming switch is normal.

NO >> Replace the headlamp aiming switch.

...

Oil filter

Removal and Installation

REMOVAL

1. Remove engine under cover.

2. Using oil filter wrench [SST: KV10115801 (J-38956)] (A), remove

oil filter.

: Vehicle front

CAUTION:

• Oil filter is provided with relief valve. Use genuine NISSAN

oil filter or equivalent.

• Be careful not to get burned when ...