Nissan Juke Service and Repair Manual : Wheel alignment

Inspection

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE

:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full.

Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

• Tires for improper air pressure and wear

• Road wheels for runout: refer to WT-7, "Inspection".

• Wheel bearing axial end play: refer to RAX-12, "Inspection".

• Shock absorber operation • Each mounting point of axle and suspension for looseness and deformation • Each of lower link, upper link, rear suspension member, suspension arm and shock absorber for cracks, deformation, and other damage • Vehicle height (posture)

CAMBER

• Measure camber of both right and left wheels with a suitable alignment gauge.

Camber : Refer to RSU-37, "Wheel Alignment".

• If camber is outside specified range, adjust with adjusting bolt in rear lower link. Refer to RSU-21, "Adjustment".

TOE-IN

Measure toe-in by the following procedure.

WARNING:

• Always perform the following procedure on a flat surface.

• Check that no person is in front of vehicle before pushing it.

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

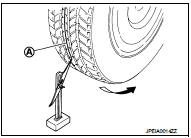

3. Put matching mark (A) on base line of the tread (rear side) of both tires at the same height of hub center. These are measuring points.

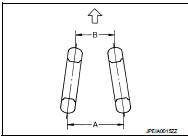

4. Measure distance (A) (rear side).

: Vehicle front

5. Push vehicle slowly ahead to rotate wheels 180 degrees (1/2 turn).

NOTE

:

If the wheels rotates more than 180 degrees (1/2 turn), start this

procedure again from the beginning. Do not push the vehicle

backward.

6. Measure distance (B) (front side).

Total toe-in = A − B Total toe-in : Refer to RSU-37, "Wheel Alignment".

• If toe-in is outside specified range, adjust with adjusting bolt in upper link and lower link. Refer to RSU- 21, "Adjustment".

Adjustment

CAMBER, TOE-IN

CAUTION:

• Adjust camber first, then adjust toe-in last. never change the order.

• If camber angle needs to be adjusted, toe-in adjustment is necessary.

• Minimize difference of left and right toe-in within tolerance

.

1. Loosen mounting nuts of upper link and lower link on the suspension member side.

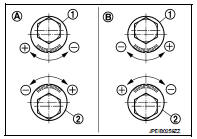

2. Adjust camber and toe-in by turning upper link adjusting bolt (1) and lower link adjusting bolt (2) alternately.

A : Left side

B : Right side

NOTE:

Upper link adjusting bolt Positive direction : Upper link slides into inner side of vehicle.

Negative direction : Upper link slides into outer side of vehicle.

Lower link adjusting bolt Positive direction : Lower link slides into outer side of vehicle.

Negative direction : Lower link slides into inner side of vehicle.

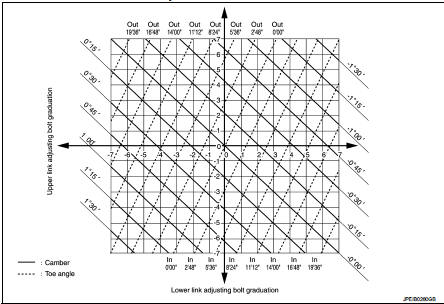

• Refer to the table below for easier adjustment

- Obtain the amount of camber and toe-in by calculating the difference between the measurement result and the standard value.

- Obtain the needed adjustment amount from the graph and move adjusting bolts, respectively.

3. After adjustment, tighten mounting nuts of upper link and lower link on the suspension member side.

CAUTION:

When tightening nut to the specified torque, the bolt must be fixed with a

wrench.

Rear suspension assembly

Rear suspension assembly

Inspection

MOUNTING INSPECTION

Check the mounting conditions (looseness, backlash) of each component and

component conditions (wear,

damage) are normal.

SHOCK ABSORBER

Check for oil leakage a ...

Other materials:

Diagnosis system (IPDM E/R)

Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following

systems to check their operation.

• Oil pressure warning lamp (only for K9K engine models)

• Rear window defogger

• Front wiper motor

• Parking lamp

• License p ...

Cooling fan

Exploded View

1. Fan motorCooling fan

2. Fan shroud

3. Cooling fan

A. Reverse screw

: Apply thread locking sealant.

: Vehicle front

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-62, "Draining".

2. Disconnect radiator hose (lower) c ...

P2100 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF and wait at least 4 minutes.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2 ...