Nissan Juke Service and Repair Manual : Precautions

Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

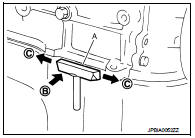

• After removing mounting nuts and bolts, separate the mating surface using the seal cutter [SST: KV10111100 (J-37228)] (A) and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap the seal cutter [SST: KV10111100 (J-37228)] to insert it (B), and then slide it (C) by tapping on the side as shown in the figure.

• In areas where the seal cutter [SST: KV10111100 (J-37228)] is difficult to use, lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

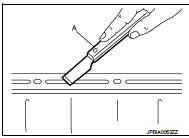

1. Using a scraper (A), remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

• Remove liquid gasket completely from the groove of the liquid gasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove adhering moisture, grease and foreign materials.

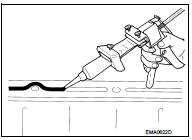

3. Attach liquid gasket tube to the tube presser (commercial service tool).

Use Genuine Liquid Gasket or equivalent.

4. Apply liquid gasket without gaps to the specified location according to the specified dimensions.

• If there is a groove for liquid gasket application, apply liquid gasket to the groove.

• As for bolt holes (B), normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Check to read the text of this manual.

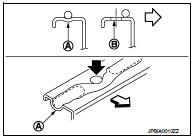

A : Groove

: Inside

: Inside

• Within five minutes of liquid gasket application, install the mating component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten mounting bolts or nuts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

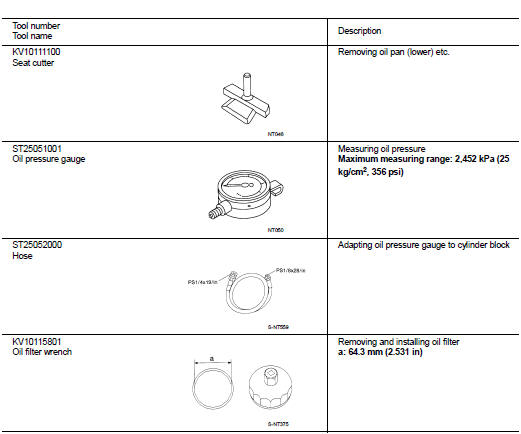

Special Service Tools

Commercial Service Tools

Description

Description

Engine Lubrication System

Engine Lubrication System Schematic

...

Other materials:

Mainshaft and gear

Exploded View

1. Mainshaft front bearing outer

race

2. Mainshaft front bearing inner race

3. Mainshaft

4. 1st main gear

5. 1st inner baulk ring

6. 1st synchronizer cone

7. 1st outer baulk ring

8. 1st-2nd coupling sleeve

9. Insert key

10. 1st-2nd synchronizer hub

11. 2nd outer baulk ...

Front washer nozzle and tube

Exploded View

LHD models

1. Front washer nozzle LH

2. Front washer nozzle RH

3. Cowl top cover

4. Front washer tube (tank side)

5. Front washer tube RH

6. Front washer tube LH

: Vehicle front

Hydraulic Layout

1. Front washer nozzle

2. Check valve

3. Front washer

4. Washer tank ...

Vehicle speed sensing auto lock operation does not operate

Diagnosis Procedure

1.CHECK “AUTOMATIC LOCK/UNLOCK SELECT” SETTING IN “WORK SUPPORT”

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT” mode.

3. Check “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT”.

Refer to DLK-217, "DOOR LOCK ...