Nissan Juke Service and Repair Manual : Periodic maintenance

REAR PROPELLER SHAFT

Inspection

APPEARANCE AND NOISE

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, inspect propeller shaft runout first.

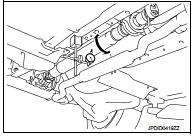

1. With a dial indicator, measure propeller shaft runout at runout measuring points by rotating final drive companion flange with hands.

Propeller shaft runout : Refer to DLN-125, "Propeller Shaft Runout".

• Propeller shaft runout measuring point (Point “

”)

: Front

: Front

Dimension A: 542 mm (21.34 in) B: 516.5 mm (20.33 in)

2. If runout still exceeds specifications, separate propeller shaft at final drive companion flange or transfer companion flange; then change the phase between companion flange and propeller shaft by the one bolt hole at a time and install propeller shaft.

3. Check runout again. If runout still exceeds specifications, replace propeller shaft assembly.

4. Check the vibration by driving vehicle.

Symptom diagnosis

Symptom diagnosis

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

Use the chart below to find the cause of the symptom. If necessary, repair or

replace these parts.

×: Applic ...

Removal and installation

Removal and installation

REAR PROPELLER SHAFT ...

Other materials:

B1080, B1096 driver air bag module

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

On board diagnostic (OBD) system

Description

This is an onboard diagnosis system which records diagnosis information

related to the exhaust gases. It

detects malfunctions related to sensors and actuators. The malfunctions are

indicated by means of the malfunction

indicator lamp (MIL) and are stored as DTC in the ECU memory. ...

How to use touch screen

CAUTION

• The glass screen on the liquid crystal display may break if it is hit with

a hard or sharp object. If the glass screen breaks, do not touch it.

Doing so could result in an injury.

• To clean the display, never use a rough cloth, alcohol, benzine, thinner or any

kind of solvent or pa ...