Nissan Juke Service and Repair Manual : P1585 G sensor

Description

• G sensor is installed to floor under instrument lower cover.

• G sensor detects longitudinal G and inclination that affects the vehicle and outputs to ECM using analog voltage.

ECM converts the analog voltage value to digital signal and transmits the signal to TCM via CAN communication.

• TCM detects longitudinal G and inclination of the vehicle using information of CAN communication.

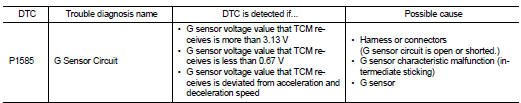

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

1.PRECONDITIONING

Immediately after performing any “DTC CONFIRMATION PROCEDURE”, always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

With CONSULT-III

1. Start the engine.

2. Select “Data Monitor” in “TRANSMISSION”.

3. Select “VEHICLE SPEED”.

4. Using the “D” position, increase vehicle speed in constant acceleration within 5 seconds.

5. Select “Self Diagnostic Results” in “TRANSMISSION”.

Is “P1585” detected? YES >> Go to TM-236, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

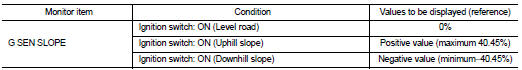

1.CHECK G SENSOR SIGNAL

With CONSULT-III

With CONSULT-III

1. Park vehicle on level surface.

2. Turn ignition switch ON.

3. Select “Data Monitor” in “TRANSMISSION”.

4. Select “G SEN SLOPE”.

5. Check display of “G SEN SLOPE”.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 2.

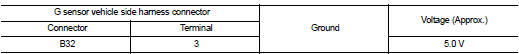

2.CHECK G SENSOR POWER SOURCE

1. Turn ignition switch OFF.

2. Disconnect G sensor connector.

3. Turn ignition switch ON.

4. Check voltage between G sensor vehicle side harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 7.

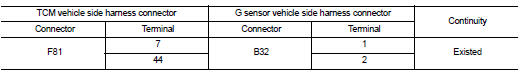

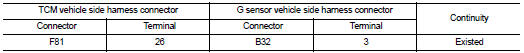

3.CHECK HARNESS BETWEEN TCM AND G SENSOR (PART 1)

1. Turn ignition switch OFF.

2. Disconnect TCM connectors.

3. Check continuity between TCM vehicle side harness connector terminals and G sensor vehicle side harness connector terminals.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK HARNESS BETWEEN TCM AND G SENSOR (PART 2)

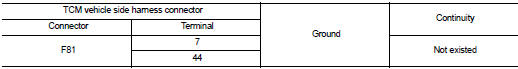

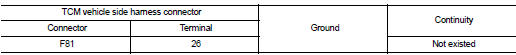

Check continuity between TCM vehicle side harness connector terminals and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

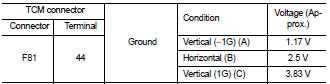

5.CHECK G SENSOR

1. Remove G sensor. Refer to TM-282, "Removal and Installation".

2. Reconnect all the connectors.

3. Turn ignition switch ON.

4. Check voltage between TCM connector terminal and ground.

: Direction of gravitational

: Direction of gravitational

force

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace G sensor. Refer to TM-282, "Removal and Installation".

6.PERFORM CALIBRATION

1. Install G sensor. Refer to TM-282, "Removal and Installation".

2. Select “Self Diagnostic Results” in “TRANSMISSION”.

3. Select “Erase”.

4. Perform “G SENSOR REMOVAL/INSTALLATION AND REPLACEMENT”. Refer to TM-182, "Description".

Is calibration complete normally? YES >> INSPECTION END

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

7.CHECK HARNESS BETWEEN TCM AND G SENSOR (SENSOR POWER CIRCUIT) (PART 1)

1. Turn ignition switch OFF.

2. Disconnect TCM connectors.

3. Check continuity between TCM vehicle side harness connector terminal and G sensor vehicle side harness connector terminal.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace damaged parts.

8.CHECK HARNESS BETWEEN TCM AND G SENSOR (SENSOR POWER CIRCUIT) (PART 2)

Check continuity between TCM vehicle side harness connector terminal and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace damaged parts.

Special Repair Requirement

1.PERFORM G SENSOR CALIBRATION

Perform “G SENSOR REMOVAL/INSTALLATION AND REPLACEMENT”.

>> Refer to TM-182, "Description".

P0868 transmission fluid pressure

P0868 transmission fluid pressure

Description

The secondary pressure solenoid valve regulates the secondary pressure to

suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC C ...

P1701 TCM

P1701 TCM

Description

When the power supply to the TCM is cut OFF, for example because the battery

is removed, and the self-diagnosis

memory function stops, malfunction is detected.

NOTE:

Since “P1701” ...

Other materials:

P1865 gear ratio signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...

Inspection

LEVEL

• Check that the reservoir tank engine coolant level is within the

“MIN” to “MAX” when the engine is cool.

A : MAX

B : MIN

• Adjust the engine coolant level if necessary.

LEAKAGE

• To check for leakage, apply pressure to the cooling system with the

radiator cap tester (commercial ser ...

P159B G sensor

For M/T models : DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. T ...