Nissan Juke Service and Repair Manual : P0327, P0328 KS

DTC Logic

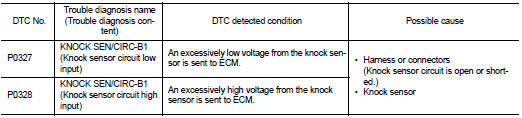

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and run it for at least 5 seconds at idle speed.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-269, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

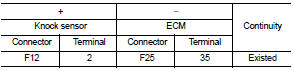

1.CHECK KNOCK SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect knock sensor harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between knock sensor harness connector and ECM harness connector.

5. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

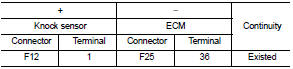

2.CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between knock sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK KNOCK SENSOR

Check the knock sensor. Refer to EC-270, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace knock sensor. Refer to EM-103, "Exploded View".

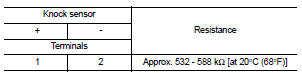

Component Inspection

1.CHECK KNOCK SENSOR

1. Turn ignition switch OFF.

2. Disconnect knock sensor harness connector.

3. Check resistance between knock sensor terminals as per the following.

NOTE

:

It is necessary to use an ohmmeter which can measure more than 10 MΩ.

CAUTION:CAUTION: Do not use any knock sensors that have been dropped or physically damaged. Use only new ones.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace knock sensor. Refer to EM-103, "Exploded View".

Do not use any knock sensors that have been dropped or physically damaged. Use only new ones.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace knock sensor. Refer to EM-103, "Exploded View".

P0300, P0301, P0302, P0303, P0304 misfire

P0300, P0301, P0302, P0303, P0304 misfire

DTC Logic

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, ECM can ...

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643.

Refer to EC-307, "DTC Logic".

DTC CONFIRMATION PRO ...

Other materials:

Ignition coil, spark plug and rocker cover

Exploded View

1. Ignition coil

2. Spark plug

3. Rocker cover

4. Hose cramp

5. PCV hose

6. PCV valve

7. O-ring

8. Gasket

9. Oil filler cap

10. O-ring

11. Camshaft position sensor (INT)

12. Camshaft position sensor (EXH)

13. Cramp

A. To intake manifold

: Always replace after e ...

On board diagnostic (OBD) system

Diagnosis Description

DESCRIPTION

The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD) performed by

the TCM in combination with

the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp)

and is stored as a DTC ...

Commercial Service Tools

CAUTION:

• Every time the vehicle is lifted up, maintain the complete vehicle curb

condition.

• Since the vehicle's center of gravity changes when removing main parts on the

front side (engine,

transmission, suspension etc.), support a jack up point on the rear side garage

jack with a mis ...