Nissan Juke Service and Repair Manual : Exhaust manifold

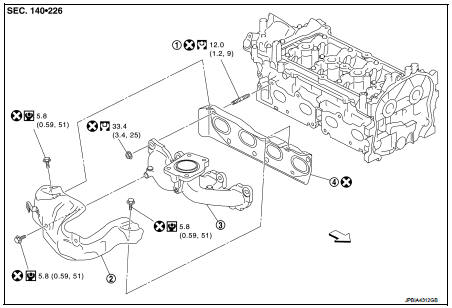

Exploded View

1. Stud bolt

2. Exhaust manifold cover

3. Exhaust manifold

4. Gasket

Engine front

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-11, "Draining".

2. Remove turbocharger. Refer to EM-36, "Exploded View".

3. Remove catalyst convertor. Refer to EM-33, "2WD : Exploded View" (2WD models) or EM-34, "4WD : Exploded View" (4WD models).

4. Remove exhaust manifold cover.

5. Remove exhaust manifold.

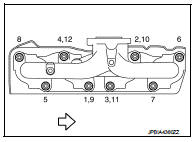

• Loosen nuts in reverse order as shown in the figure.

: Engine front

: Engine front

NOTE:

Disregard the numerical order No. 9 to 12 in removal.

6. Remove gasket.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSTALLATION

1. Install gasket to cylinder head as shown in the figure.

: Engine front

: Engine front

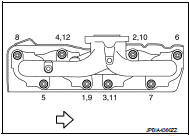

2. Install exhaust manifold with the following procedure: a. Tighten nuts in numerical order as shown in the figure.

: Engine front

: Engine front

NOTE

:

• Tighten nuts the No.1 to No.4 in two steps.

• The numerical order No.9 to No.12 shows the second step.

3. Install remaining parts in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

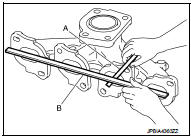

Surface Distortion

• Using feeler gauge (A) and straightedge (B), check the surface distortion

of exhaust manifold mating surface in each exhaust port

and entire part.

Limit : Refer to EM-130, "Exhaust Manifold".

• If it exceeds the limit, replace exhaust manifold.

Turbocharger

Turbocharger

Exploded View

1. Heat insulator

2. Actuator hose

3. Clamp

4. Turbocharger inlet tube

5. Gasket

6. Gasket

7. Clamp

8. Oil outlet hose

9. Oil return pipe

10. Oil supply tube

11. O-ri ...

Oil pan (lower)

Oil pan (lower)

Exploded View

1. O-ring

2. Oil pan (upper)

3. Oil level gauge guide

4. O-ring

5. Oil level gauge

6. Oil pump drive chain

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump chain ...

Other materials:

Instrument panel assembly

Exploded View

LHD models

1. Front passenger air bag module

2. Instrument panel assembly

3. Instrument side finisher LH

4. Combination meter

5. Cluster lid A

6. Push-button ignition switch

7. Steering column upper cover

8. Steering lock escutcheon

9. Steering column lower cover

10. ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Precaution Necessary for Steering Wheel Rotation

after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the push-button

ignition switch to the LOCK position,

then disconnect both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Alw ...