Nissan Juke Service and Repair Manual : Evaporative emission system

Inspection

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections, chafing and deterioration.

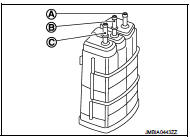

2. Check EVAP canister as follows: a. Block port (A). Orally blow air through port (B).

Check that air flows freely through port (C).

b. Block port (B). Orally blow air through port (A).

Check that air flows freely through port (C).

3. Visually inspect the fuel check valve for cracks, damage, loose connections chafing and deterioration.

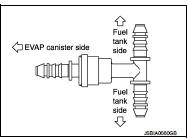

4. Check fuel check valve as follows: a. Blow air through connector on the fuel tank side. A considerable resistance should be felt and a portion of air flow should be directed toward the EVAP canister side.

b. Blow air through connector on EVAP canister side. Air flow should be smoothly directed toward fuel tank side.

c. If fuel check valve is suspected or not properly functioning in step 1 and 2 above, replace it.

5. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

a. Wipe clean valve housing.

b. Check valve opening pressure and vacuum.

Pressure:

15.3 - 20.0 kPa (0.153 - 0.200 bar, 0.156 - 0.204 kg/

cm2, 2.22 - 2.90 psi)

Vacuum:

–6.0 to –3.4 kPa (–0.06 bar to –-0.034bar, –0.061 to –

0.035 kg/cm2, –0.87 to –0.49 psi)

c. If out of specification, replace fuel filler cap as an assembl

Ignition timing

Ignition timing

Inspection

1.CHECK IGNITION TIMING

1. Attach timing light to loop wire as shown.

1. Loop wire

A. Timing light

B. Timing indicator

2. Check ignition timing.

>> INSPECTION END ...

Positive crankcase ventilation

Positive crankcase ventilation

Inspection

1.CHECK PCV VALVE

With engine running at idle, remove PCV valve from rocker cover. A

properly working valve makes a hissing noise as air passes through

it. A strong vacuum should be fel ...

Other materials:

C1101, C1102, C1103, C1104 WHEEL SENSOR

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

Treadwear

The treadwear grade is a comparative rating based on the wear rate of the tire

when tested under controlled conditions on a specified government test course. For

example, a tire graded 150 would wear one and one-half (1 1/2) times as well on

the government course as a tire graded 100. The rela ...

Vehicle information

BODY EXTERIOR PAINT COLOR

Body Exterior Paint Color

FOR 2WD MODELS

NOTE:

• S: Solid

• 2S: Solid + Clear

• CS: Color clear solid

• M: Metallic

• P: 2-Coat pearl

• 3P: 3-Coat pearl

• FPM: Iron oxide pearl

• RPM: Multi flex color

• TM: Micro titanium metallic

• PM: Pearl metallic

FOR ...