Nissan Juke Service and Repair Manual : C1101, C1102, C1103, C1104 wheel sensor

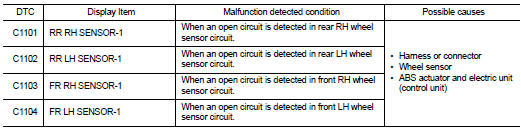

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Stat the engine.

2. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

3. Stop the vehicle.

4. Perform self-diagnosis for “ABS”.

Is DTC “C1101”, “C1102”, “C1103” or “C1104” detected? YES >> Proceed to BRC-151, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedur

CAUTION:

Never check between wheel sensor harness connector terminals.

1.CHECK WHEEL SENSOR

1. Turn the ignition switch OFF.

2. Check wheel sensor for damage.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.REPLACE WHEEL SENSOR (1)

With CONSULT-III.

With CONSULT-III.

1. Replace wheel sensor.

- Front: Refer to BRC-224, "FRONT WHEEL SENSOR : Removal and Installation".

- Rear: Refer to BRC-227, "REAR WHEEL SENSOR : Removal and Installation".

2. Erase Self-diagnosis result for “ABS”.

3. Turn the ignition switch OFF, and wait 10 seconds or more.

4. Stat the engine.

5. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

6. Stop the vehicle.

7. Perform self-diagnosis for “ABS”.

Is DTC “C1101”, “C1102”, “C1103” or “C1104” detected? YES >> GO TO 3.

NO >> INSPECTION END

3.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Check ABS actuator and electric unit (control unit) harness connector for disconnection or looseness.

3. Check wheel sensor harness connector for disconnection or looseness.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts, securely lock the connector, and GO TO 4.

4.PERFORM SELF-DIAGNOSIS (1)

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Stat the engine.

4. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

5. Stop the vehicle.

6. Perform self-diagnosis for “ABS”.

Is DTC “C1101”, “C1102”, “C1103” or “C1104” detected? YES >> GO TO 5.

NO >> INSPECTION END

5.CHECK TERMINAL

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector and then check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

3. Disconnect wheel sensor harness connector and check each wheel sensor pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts and GO TO 6.

6.PERFORM SELF-DIAGNOSIS (2)

With CONSULT-III.

With CONSULT-III.

1. Connect ABS actuator and electric unit (control unit) harness connector.

2. Connect wheel sensor harness connector.

3. Erase Self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF, and wait 10 seconds or more.

5. Stat the engine.

6. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

7. Stop the vehicle.

8. Perform self-diagnosis for “ABS”.

Is DTC “C1101”, “C1102”, “C1103” or “C1104” detected? YES >> GO TO 7.

NO >> INSPECTION END

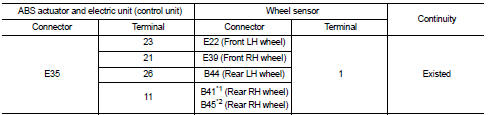

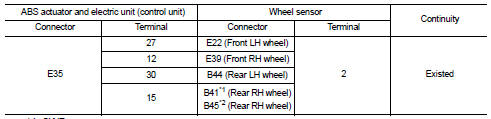

7.CHECK WHEEL SENSOR HARNESS

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Disconnect wheel sensor harness connector.

4. Check continuity between ABS actuator and electric unit (control unit) harness connector and wheel sensor harness connector. (Check continuity when steering wheel is steered to RH and LH, or center harness in wheel housing is moved.)

Measurement connector and terminal for power supply circuit

*1: 2WD

*2: 4WD

Measurement connector and terminal for signal circuit

*1: 2WD

*2: 4WD

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts and GO TO 8.

8.PERFORM SELF-DIAGNOSIS (3)

With CONSULT-III.

With CONSULT-III.

1. Connect ABS actuator and electric unit (control unit) harness connector.

2. Connect wheel sensor harness connector.

3. Erase Self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF, and wait 10 seconds or more.

5. Stat the engine.

6. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

7. Stop the vehicle.

8. Perform self-diagnosis for “ABS”.

Is DTC “C1101”, “C1102”, “C1103” or “C1104” detected? YES >> GO TO 9.

NO >> INSPECTION END

9.REPLACE WHEEL SENSOR

With CONSULT-III.

With CONSULT-III.

1. Replace wheel sensor.

- Front: Refer to BRC-224, "FRONT WHEEL SENSOR : Removal and Installation".

- Rear: Refer to BRC-227, "REAR WHEEL SENSOR : Removal and Installation".

2. Erase Self-diagnosis result for “ABS”.

3. Turn the ignition switch OFF, and wait 10 seconds or more.

4. Stat the engine.

5. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

6. Stop the vehicle.

7. Perform self-diagnosis for “ABS”.

Is DTC “C1101”, “C1102”, “C1103” or “C1104” detected? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-233, "Removal and Installation".

NO >> INSPECTION END

C1105, C1106, C1107, C1108 wheel sensor

C1105, C1106, C1107, C1108 wheel sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Front door lock

Exploded View

1. Door key cylinder assembly (driver

side)

Outside handle escutcheon (passenger

side)

2. Rear gasket

3. Outside handle bracket

4. TORX bolt

5. Key rod (driver side)

6. Door lock assembly

7. Inside handle

8. Outside handle

9. Front gasket

10. Cable clip

: Pawl

: V ...

Foreword

This manual contains maintenance and repair procedures for the NISSAN

JUKE, model F15 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely unde ...

Precautions for Drive Shaft

• Observe the following precautions when disassembling and assembling drive

shaft.

- Never disassemble joint sub-assembly because it is non-overhaul parts.

- Perform work in a location which is as dust-free as possible.

- Clean the parts, before disassembling and assembling.

- Prevent the entr ...