Nissan Juke Service and Repair Manual : A/C switch

Component Function Check

1.CHECK A/C ON SIGNAL

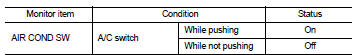

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “AIR COND SW” in “DATA MONITOR” mode, and check status under the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to HAC-281, "Diagnosis Procedure".

Diagnosis Procedure

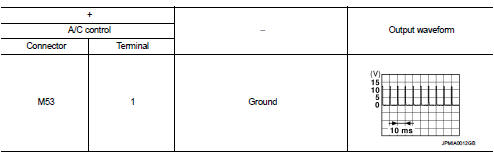

1.CHECK A/C SWITCH POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect A/C control connector.

3. Turn ignition switch ON.

4. Check output waveform between A/C control harness connector and ground with using oscilloscope.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 3.

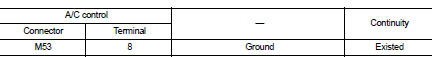

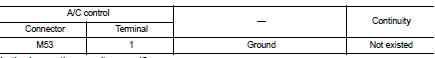

2.CHECK A/C SWITCH GROUND CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between A/C control harness connector and ground.

Is the inspection result normal? YES >> Replace A/C control. Refer to HAC-239, "Removal and Installation".

NO >> Repair harness or connector.

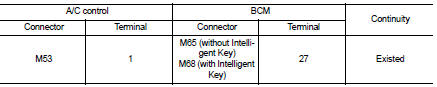

3.CHECK A/C SWITCH POWER SUPPLY CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between A/C control harness connector and BCM harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair harness or connector.

4.CHECK A/C SWITCH POWER SUPPLY CIRCUIT FOR SHORT

Check continuity between A/C control harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation" (with Intelligent Key) or BCS-161, "Removal and Installation" (without Intelligent Key).

NO >> Repair harness or connector.

Power supply and ground circuit

Power supply and ground circuit

PTC HEATER CONTROL UNIT : Diagnosis Procedure

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10A fuses (No. 3 and 7).

NOTE:

Refer to PG-23, "Fuse and Fusible Link Arrangement".

...

Blower fan on signal

Blower fan on signal

Component Function Check

1.CHECK BLOWER FAN ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “FAN ON SIG” in “DATA MONITOR” ...

Other materials:

Cylinder head

Exploded View

REMOVAL

1. Cylinder head assembly

2. Cylinder head bolt

3. Washer

4. Cylinder head gasket

A.Tightening must be done following the installation procedure.

Refer to EM-209

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: Should be lubricated with oil.

D ...

Precaution for Diesel Equipment

CLEANLINESS

CLEANLINESS INSTRUCTIONS WHICH MUST BE FOLLOWED WHEN WORKING ON THE HIGH

PRESSURE

DIRECT INJECTION SYSTEM

Risks relating to contamination

The system is very sensitive to contamination. The risks caused by the

introduction of contamination are:

• Damage or destruction of the high ...

Brake fluid

Inspection

BRAKE FLUID LEVEL

• Check that the fluid level in the reservoir tank is within the specified

range (MAX – MIN lines).

• Visually check for any brake fluid leakage around the reservoir

tank.

• Check the brake system for any leakage if the fluid level is

extremely low (lower than MIN ...