Nissan Juke Service and Repair Manual : Valve oil seal

VALVE OIL SEAL : Removal and Installation

REMOVAL

1. Remove camshafts. Refer to EM-78, "Exploded View".

2. Remove valve lifters. Refer to EM-78, "Exploded View".

3. Rotate crankshaft, and set piston whose valve oil seal is to be removed to TDC. This will prevent valve from dropping into cylinder.

CAUTION:

When rotating crankshaft, be careful to avoid scarring front cover with timing

chain.

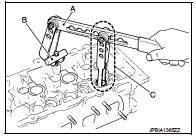

4. Remove valve collet.

• Compress valve spring with the valve spring compressor [SST: KV10116200 (J-26336-A)] (A), the attachment [SST: KV10115900 (J-26336-20)] (C), and the adapter [SST: KV10109220 ( — )] (B). Remove valve collet with magnet hand.

CAUTION:

Be careful not to damage valve lifter holes.

5. Remove valve spring retainer and valve spring (with valve spring seat).

CAUTION:

Never remove valve spring seat from valve spring.

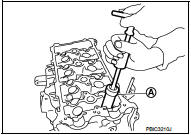

6. Remove valve oil seal with the valve oil seal puller [SST: KV10107902 (J-38959)] (A).

INSTALLATION

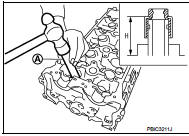

1. Apply new engine oil to valve oil seal joint surface and seal lip.

2. Press in valve oil seal to the height (H) shown in the figure with the valve oil seal drift [SST: KV10115600 (J-38958)] (A).

Height (H) : 15.1 - 15.7 mm (0.594 - 0.618 in)

3. Install in the reverse order of removal, for the rest of parts.

Oil seal

Oil seal

...

Front oil seal

Front oil seal

FRONT OIL SEAL : Removal and Installation

REMOVAL

1. Remove the following parts.

• Front fender protector (RH): Refer to EXT-22, "Exploded View".

• Drive belt: Refer to EM-20, "Expl ...

Other materials:

Fuel Efficient Driving Tips

Follow these easy-to-use Fuel Efficient Driving Tips to help you achieve the

most fuel economy from your vehicle.

1. Use smooth accelerator and brake pedal application.

• Avoid rapid starts and stops.

• Use smooth, gentle accelerator and brake application whenever possible.

• ...

Diagnosis system (BCM)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...

B1122, B1123, B1124, B1125, B1126, B1127 diagnosis sensor unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...