Nissan Juke Service and Repair Manual : Unlock sensor

Component Function Check

1.CHECK FUNCTION

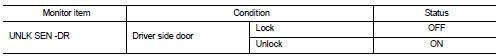

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “UNLK SEN -DR” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Unlock sensor is OK.

NO >> Refer to DLK-270, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BCM OUTPUT SIGNAL

1. Turn ignition switch OFF.

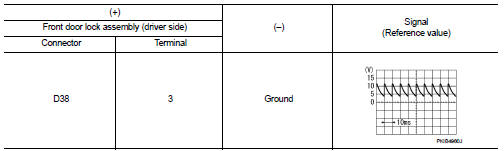

2. Disconnect front door lock assembly (driver side) connector.

3. Check signal between front door lock assembly (driver side) harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK UNLOCK SENSOR CIRCUIT

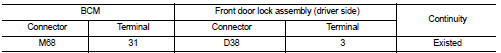

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and front door lock assembly (driver side) harness connecto

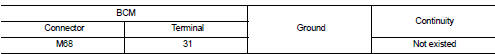

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

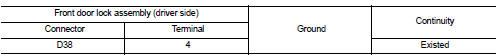

3.CHECK UNLOCK SENSOR GROUND CIRCUIT

Check continuity between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK UNLOCK SENSOR

Refer to DLK-271, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace front door lock assembly (driver side).

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

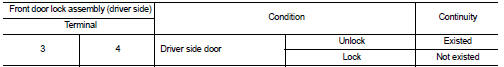

1.CHECK UNLOCK SENSOR

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check continuity between front door lock assembly (driver side) terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace front lock assembly (driver side).

Shift P warning lamp

Shift P warning lamp

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “LCD” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to t ...

Other materials:

P0171 fuel injection system function

DTC Logic

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture

ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the

A/F sensor 1. The ECM calculates

the necessary compensation to correct the ...

Brake pedal

Inspection and Adjustment

INSPECTION

Brake Pedal Height

Check the height (H1) between the dash lower panel (1) and the

brake pedal upper surface.

H1 : Refer to BR-136, "Brake Pedal".

CAUTION:

Remove the floor trim.

Stop Lamp Switch

Check the clearance (C) among the brake pedal l ...

Battery inspection

How to Handle Battery

CAUTION:

• If it becomes necessary to start the engine with a booster battery and jumper

cables, use a 12-volt

booster battery.

• After connecting battery cables, ensure that they are tightly clamped to

battery terminals for good

contact.

• Never add distilled water t ...