Nissan Juke Service and Repair Manual : Unit disassembly and assembly

Torque converter and converter housing oil seal

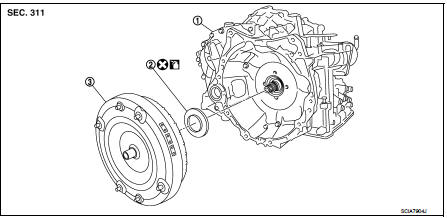

Exploded View

1. Transaxle assembly 2. Converter housing oil seal 3. Torque converter

: Always replace after every

: Always replace after every

disassembly.

: Apply CVT Fluid NS-2.

: Apply CVT Fluid NS-2.

Disassembly

1. Remove transaxle assembly. Refer to TM-301, "Removal and Installation".

2. Remove torque converter from transaxle assembly.

CAUTION:

Never damage bush on the inside of torque converter sleeve when removing torque

converter.

3. Remove converter housing oil seal using a flat-bladed screwdriver.

CAUTION:

Be careful not to scratch converter housing.

Assembly

Note the following, and install in the reverse order of removal.

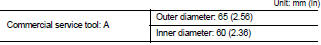

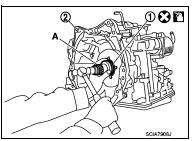

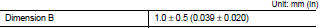

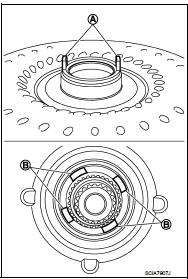

• Drive converter housing oil seal (1) evenly using a drift (A) (commercial service tool) so that converter housing oil seal protrudes by the dimension (B) respectively.

2 : Transaxle assembly

NOTE

:

Converter housing oil seal pulling direction is used as the reference.

• After completing installation, check for CVT fluid leakage and CVT fluid level. Refer to TM-184, "Inspection".

• Attach the pawl (A) of the torque converter to the drive sprocket hole (B) on the transaxle assembly side.

CAUTION:

• Rotate the torque converter for installing torque converter.

• Never damage the bushing inside the torque converter sleeve when installing the converter housing oil seal.

Inspection

INSPECTION AFTER INSTALLATION

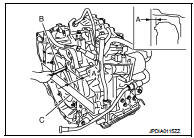

• After inserting a torque converter to the CVT, check dimension (A) with in the reference value limit.

B : Scale

C : Straightedge

Dimension (A) : Refer to TM-308, "Torque Converter".

Unit removal and installation

Unit removal and installation

Transaxle assembly

Exploded View

1. CVT fluid level gauge

2. CVT fluid charging pipe

3. O-ring

4. Transaxle assembly

5. Air breather hose

A. For tightening torque, refer to TM-301, "R ...

Other materials:

P2120 APP sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...

Diagnosis system (IPDM E/R)

With intelligent key

WITH INTELLIGENT KEY : Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following

systems to check their operation.

• Oil pressure warning lamp (only for K9K engine models)

• Rear window defogger

• F ...

System

WITH AUTO A/C

WITH AUTO A/C : System Diagram

WITH AUTO A/C : System Description

OPERATION DESCRIPTION

• BCM detects that the rear window defogger switch turns ON when the ignition

switch is ON, and then transmits

the rear window defogger switch signal to IPDM E/R via CAN communication for

...