Nissan Juke Service and Repair Manual : Structure and operation

Positive Crankcase Ventilation

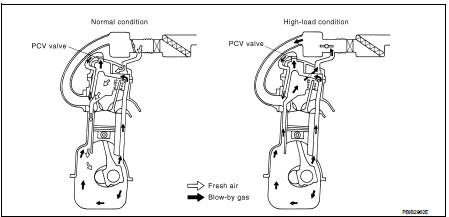

This system returns blow-by gas to the intake manifold.

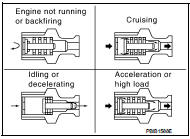

The positive crankcase ventilation (PCV) valve is provided to conduct crankcase blow-by gas to the intake manifold.

During partial throttle operation of the engine, the intake manifold sucks the blow-by gas through the PCV valve.

Normally, the capacity of the valve is sufficient to handle any blow-by and a small amount of ventilating air.

The ventilating air is then drawn from the air inlet tubes into the crankcase. In this process the air passes through the hose connecting air inlet tubes to rocker cover.

Under full-throttle condition, the manifold vacuum is insufficient to draw the blow-by flow through the valve.

The flow goes through the hose connection in the reverse direction.

On vehicles with an excessively high blow-by, the valve does not meet the requirement. This is because some of the flow will go through the hose connection to the air inlet tubes under all conditions.

Component parts

Component parts

Engine control system : Component Parts Location

1. IPDM E/R

Refer to PCS-5, "Component Parts

Location".

2. Battery current sensor

(with battery temperature sensor)

3. Mass air flow ...

System

System

Engine control system : System Diagram

Engine control system : System Description

ECM performs various controls such as fuel injection control and ignition

timing control.

MULTIPORT FUEL INJE ...

Other materials:

Component parts

Component Parts Location

1. Parking brake switch

2. Seat belt buckle switch (passenger

side)

3. Occupant detection unit

(Under the passenger seat cushion

pad)

4. ABS actuator and electric unit (control

unit)

Refer to BRC-97, "Component Parts

Location" (with ESP).

Refer to B ...

Speed limiter main switch

Component Function Check

1.CHECK SPEED LIMITER MAIN SWITCH FUNCTION

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals under the following

conditions

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-1020, "Diagnosi ...

G sensor

Exploded View

1. G sensor

: Vehicle front

: N·m (kg-m, in-lb)

Removal and Installation

CAUTION:

• Never drop or strike G sensor, because it has little tolerance for impact.

• Never use a power tool to avoid impact.

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer ...