Nissan Juke Service and Repair Manual : PTC heater

Component Function Check

1.CHECK PTC HEATER OPERATION

1. Start the engine.

2. Operate fan control dial.

3. Operate temperature control dial to full hot position.

4. Check for warm air at discharge air outlet.

NOTE

:

• Engine must be cold.

• Battery must be charged.

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to HAC-294, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK FUSE AND FUSIBLE LINK

1. Turn ignition switch OFF.

2. Check 30A fuses (Nos. 32 and 36) and 40A fusible link (letter F).

NOTE

:

Refer to PG-23, "Fuse and Fusible Link Arrangement".

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is blown.

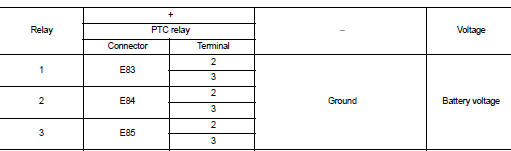

2.CHECK PTC RELAY POWER SUPPLY

1. Disconnect PTC relay connector.

2. Turn ignition switch ON.

3. Check voltage between PTC relay harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair harness or connector between PTC relay and fuse or fusible link.

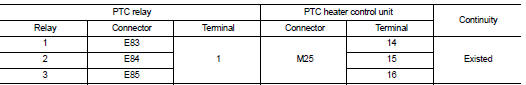

3.CHECK PTC RELAY CONTROL SIGNAL CIRCUIT FOR OPEN

1. Disconnect PTC heater control unit connector.

2. Check continuity between PTC relay harness connector and PTC heater control unit harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair harness or connector.

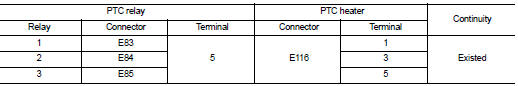

4.CHECK PTC HEATER POWER SUPPLY CIRCUIT FOR OPEN

Check continuity between PTC relay harness connector and PTC heater harness connector

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair harness or connector.

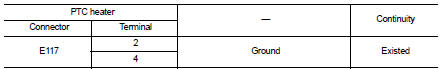

5.CHECK PTC HEATER GROUND CIRCUIT FOR OPEN

Check continuity between PTC heater harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair harness or connector.

6.CHECK PTC RELAY

Check PTC relay. Refer to HAC-295, "Component Inspection (PTC Relay)".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace malfunctioning PTC relay.

7.CHECK PTC HEATER

Check PTC heater. Refer to HAC-296, "Component Inspection (PTC Heater)".

Is the inspection result normal? YES >> Replace PTC heater control unit.

NO >> Replace PTC heater.

Component Inspection (PTC Relay)

1.CHECK PTC RELAY

1. Remove PTC relay.

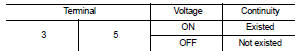

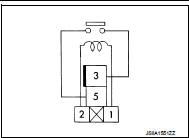

2. Check continuity between PTC relay terminals 3 and 5 when the voltage is supplied between terminals 1 and 2.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunctioning PTC relay.

Component Inspection (PTC Heater)

1.CHECK PTC HEATER

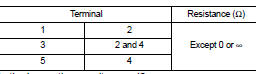

Check resistance between PTC heater terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace PTC heater.

Magnet clutch

Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis

Description" (with Intelligent Key) or PCS-

43, "Diagnosi ...

Other materials:

P0225 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P0225 is displayed with DTC P0641, first perform trouble diagnosis for

DTC P0641. Refer to

EC-974, "DTC Logic".

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Grou ...

Turbocharger boost control

Turbocharger boost control : SystemDiagram

Turbocharger boost control : System Description

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

Depending on driving conditions, the ECM performs ON/OFF duty control of the

turbocharger boost control

solenoid valve and controls the boost by adjustin ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation o ...