Nissan Juke Service and Repair Manual : Power generation voltage variable control system operation inspection

Inspection Procedure

CAUTION:

When performing this inspection, always use a charged battery that has completed

the battery inspection.

(When the charging rate of the battery is low, the response speed of the voltage change will become slow. This can cause an incorrect inspection.)

1.CHECK ECM (CONSULT-III)

Perform ECM self-diagnosis with CONSULT-III. Refer to EC-501, "CONSULT-III Function" (MR16DDT), or EC-835, "CONSULT-III Function" (K9K).

Self-diagnostic results content No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK OPERATION OF POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

1. Connect CONSULT-III and start the engine.

2. Check that the selector lever is in “P” or “N” position and that all of the electric loads and A/C, etc. are turned OFF.

3. Select “ALTERNATOR DUTY” at “Active Test” of “ENGINE”, and then check the value of “BATTERY VOLT” monitor when DUTY value of “ALTERNATOR DUTY” is set to 40.0 %.

“BATTERY VOLT”

2 seconds after setting the

DUTY value of “ALTERNATOR

DUTY” to 40.0 %

: 12 - 13.6 V

4. Check the value of “BATTERY VOLT” monitor when DUTY value of “ALTERNATOR DUTY” is set to 80.0%.

“BATTERY VOLT”

20 seconds after setting

the DUTY value of “ALTERNATOR

DUTY” to 80.0 %

: +0.5 V or more against

the value of “BATTERY

VOLT” monitor when

DUTY value is 40.0 %

Is the measurement value within the specification? YES >> INSPECTION END

NO >> GO TO 3.

3.CHECK IPDM E/R (CONSULT-III)

Perform IPDM E/R self-diagnosis with CONSULT-III. Refer to PCS-14, "CONSULT-III Function (IPDM E/R)" (with Intelligent Key system), PCS-45, "CONSULT-III Function (IPDM E/R)" (without Intelligent Key system).

Self-diagnostic results content

No malfunction detected>> GO TO 4.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

4.CHECK HARNESS BETWEEN ALTERNATOR AND IPDM E/R

1. Turn ignition switch OFF.

2. Disconnect alternator connector and IPDM E/R connector.

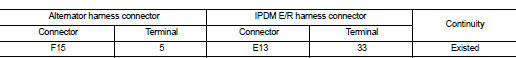

3. Check continuity between alternator harness connector and IPDM E/R harness connector.

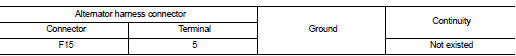

4. Check continuity between alternator harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair harness or connector between IPDM E/R and alternator.

Charging system preliminary inspection

Charging system preliminary inspection

Inspection Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair battery ter ...

Other materials:

Auto operation does not operate but manual operate normally

(driver side)

Diagnosis Procedure

1.PERFORM INITIALIZATION PROCEDURE

Initialization procedure is executed and operation is confirmed.

Refer to PWC-16, "Work Procedure".

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK ENCODER CIRCUIT

Check encoder c ...

Combination switch output circuit

Diagnosis Procedure

1.CHECK OUTPUT 1 - 5 CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check continuity between BCM harness connector and combination switch harness

connector.

Does continuity exist?

YES >> GO TO 2.

NO >> ...

Wheel alignment

Inspection

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full.

Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

• Tires for improper ai ...