Nissan Juke Service and Repair Manual : P2127, P2128 APP sensor

DTC Logic

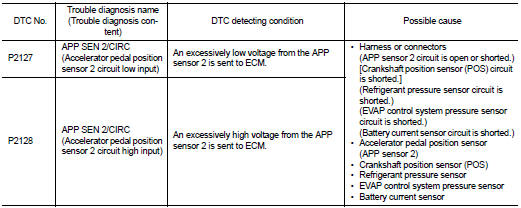

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 8 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-388, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

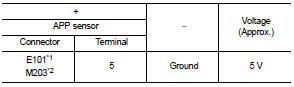

1.CHECK APP SENSOR 2 POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect accelerator pedal position (APP) sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between APP sensor harness connector and ground.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

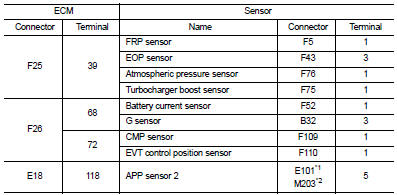

2.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals.

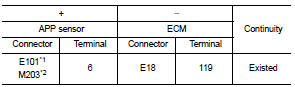

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

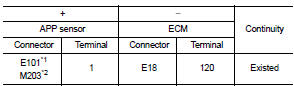

3.CHECK APP SENSOR 2 GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between APP sensor harness connector and ECM harness connector.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK APP SENSOR 2 INPUT SIGNAL CIRCUIT

1. Check the continuity between APP sensor harness connector and ECM harness connector.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts 5.CHECK APP SENSOR

Check the APP sensor. Refer to EC-390, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace accelerator pedal assembly. Refer to EM-28, "Exploded View".

Component Inspection

1.CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Turn ignition switch ON.

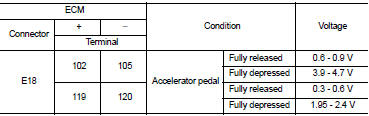

4. Check the voltage between ECM harness connector terminals as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace accelerator pedal assembly. Refer to EM-28, "Exploded View".

P2122, P2123 APP sensor

P2122, P2123 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2122 or P2123 is displayed with DTC P0643, first perform the trouble

diagnosis for DTC P0643.

Refer to EC-307, "DTC Logic".

DTC CONFIRM ...

P2135 TP sensor

P2135 TP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2135 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-307, "DTC Logic".

DTC CONFIRMATION PROCE ...

Other materials:

Oil filter

Removal and Installation

REMOVAL

1. Remove engine under cover.

2. Using oil filter wrench [SST: KV10115801] (A), remove oil filter.

: Vehicle front

CAUTION:

• Oil filter is provided with relief valve. Use genuine NISSAN

oil filter or equivalent.

• Be careful not to get burned when engine and ...

Intake valve timing control

Intake valve timing control : System Diagram

Intake valve timing control : System Description

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases continuously with the fixed

operating angle of the intakevalve.

The ECM receives signals such as ...

Hood lock

Exploded View

1. Hood lock control cable assembly

2. Hood lock assembly

: Clip

: N·m (kg-m, ft-lb)

: Body grease

Hood lock

HOOD LOCK : Removal and Installation

REMOVAL

1. Remove front center grille. Refer to EXT-18, "Removal and Installation".

2. Remove crash zone sensor. Refe ...