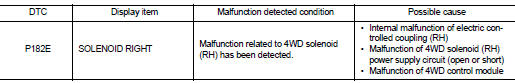

Nissan Juke Service and Repair Manual : P182E 4WD solenoid right

DTC Logic

DTC DETECTION LOGIC

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE (1)

With CONSULT-III

With CONSULT-III

1. Turn the ignition switch OFF to ON, and then wait for 5 seconds or more.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and then wait for 5 seconds or more.

4. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182E” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-57, "Diagnosis Procedure".

NO >> GO TO 3.

3.DTC REPRODUCTION PROCEDURE (2)

With CONSULT-III

With CONSULT-III

1. Lift up the vehicle.

2. Start the engine, and run at idle for 1 second.

3. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182E” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-57, "Diagnosis Procedure".

NO >> GO TO 4.

4.DTC REPRODUCTION PROCEDURE (3)

With CONSULT-III

With CONSULT-III

1. Drive the vehicle at 30 km/h (19 MPH) or more less for approximately 1 minute.

2. Stop the vehicle.

3. Drive the vehicle at 30 km/h (19 MPH) or more less for approximately 1 minute.

4. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182E” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-57, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

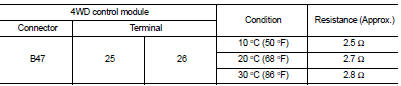

1.CHECK 4WD SOLENOID CIRCUIT (1)

1. Check the resistance between 4WD control module harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

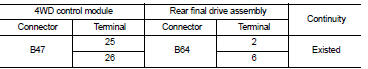

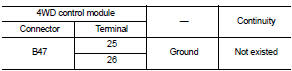

2.CHECK 4WD SOLENOID CIRCUIT (2)

1. Check the continuity between 4WD control module harness connector and rear final drive assembly harness connector.

2. Check the continuity between 4WD control module harness connector and the ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace the error-detected parts.

3.CHECK 4WD SOLENOID

Check 4WD solenoid. Refer to DLN-58, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> 4WD solenoid is malfunctioning (RH). Replace electric controlled coupling. Refer to DLN-139, "Removal and Installation".

4.CHECK TERMINALS AND HARNESS CONNECTORS

1. Check 4WD control module pin terminals for damage or loose connection with harness connector.

2. Check rear final drive assembly pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace 4WD control module. Refer to DLN-91, "Removal and Installation".

NO >> Repair or replace the error-detected parts.

Component Inspection

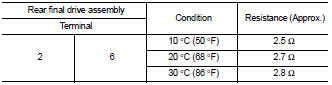

1.CHECK 4WD SOLENOID

1. Turn the ignition switch OFF.

2. Disconnect rear final drive assembly harness connector.

3. Check the resistance between rear final drive assembly connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> 4WD solenoid (RH) is malfunctioning. Replace electric controlled coupling. Refer to DLN-139, "Removal and Installation".

P182D 4WD solenoid left

P182D 4WD solenoid left

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

P182F coupling temperature sensor left

P182F coupling temperature sensor left

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any of

the cu ...

Radiator cap : Inspection

• Check valve seat (A) of radiator cap.

B : Metal plunger

- Check that valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check that valve seat has no soil and damage.

• Pull negative-pressure valve to open it, and that ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...