Nissan Juke Service and Repair Manual : P0848 transmission fluid pressure SEN/SW B

DTC Logic

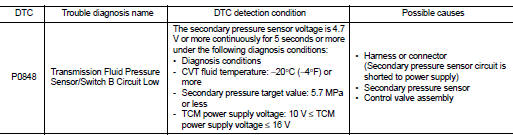

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, the ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Start the engine.

2. Select “Data Monitor” in “TRANSMISSION”.

3. Select “FLUID TEMP”.

4. Maintain the following conditions for 10 seconds or more.

FLUID TEMP : −19°C (−2.2°F) or more

5. Check the first trip DTC.

With GST.

With GST.

1. Start the engine and wait for at least 10 seconds.

CAUTION:

When the ambient temperature is −20°C (−4°F) or less and the engine is cold,

warm up the engine

for approximately 5 minutes.

2. Check the first trip DTC.

Is “P0848”detected? YES >> Go to TM-428, "Diag

Diagnosis Procedure

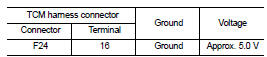

1.CHECK SECONDARY PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the CVT unit connector.

3. Turn ignition switch ON.

4. Check the voltage between CVT unit harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

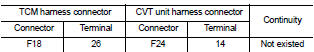

2.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the TCM harness connector terminal and the CVT unit harness connector terminal.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

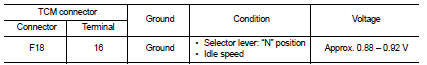

3.CHECK TCM INPUT SIGNALS

1. Connect all connectors removed.

2. Start the engine.

3. Check the voltage between TCM connector terminal and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> There is a malfunction of the secondary pressure sensor. Replace the transaxle assembly. Refer to TM-508, "Removal and Installation".

P0847 transmission fluid pressure SEN/SW B

P0847 transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

P0863 TCM communication

P0863 TCM communication

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Other materials:

Lower link

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Ref ...

Evap canister

2WD : Hydraulic Layout

EVAPORATIVE EMISSION LINE DRAWING

1.EVAP canister purge volume control

solenoid valve

2. EVAP canister

3. EAVP line

4. Fuel line

NOTE:

Do not use soapy water or any type of solvent while installing vacuum hose or

purge hoses.

2WD : Removal and Installation

REMOV ...

Cockpit

1. Outside mirror remote control switch

2. Headlight, fog light and turn signal switch

— Headlight

— Turn signal light

— Fog light

3. Steering wheel

— Electric power steering system

— Horn

— Driver’s supplemental air bag

4. Wiper and washer switch

5. Shift lever

— Continuously Variable ...