Nissan Juke Service and Repair Manual : P0826 up and down shift SW

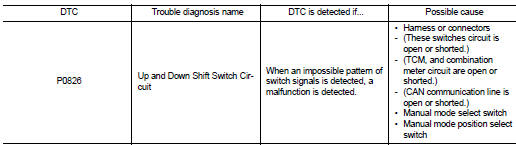

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” in “TRANSMISSION”.

3. Start engine.

4. Drive vehicle for at least 2 consecutive seconds.

MMODE : ON

Is “P0826” detected? YES >> Go to TM-227, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

1.CHECK MANUAL MODE SWITCH CIRCUIT

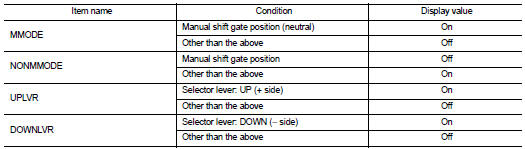

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR”.

3. Check the ON/OFF operations of each monitor item.

Without CONSULT-III

Drive the vehicle in the manual mode and shift lever to the “UP (+ side)” or “(− side)” side (1st ⇔ 6th gear).Check that the meter indicator coincides with the actual gear position.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 2.

2.CHECK MANUAL MODE SWITCH

Check manual mode switch. Refer to TM-228, "Component Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace damaged parts.

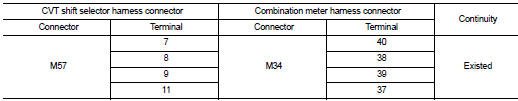

3.CHECK HARNESS BETWEEN CVT SHIFT SELECTOR HARNESS CONNECTOR AND COMBINATION METER HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect CVT shift selector harness connector and combination meter harness connector.

3. Check continuity between CVT shift selector harness connector terminals and combination meter harness connector terminals.

4. If OK, check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

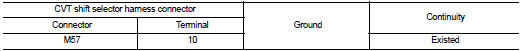

4.CHECK GROUND CIRCUIT

1. Check continuity between CVT shift selector harness connector terminals and ground.

2. If OK, check harness for short to ground and short to power.

3. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

Component Inspection

MANUAL MODE SWITCH

1.MANUAL MODE SWITCH

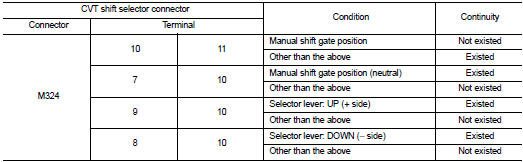

Check continuity between CVT shift selector connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair or replace damaged parts.

P0778 pressure control solenoid B

P0778 pressure control solenoid B

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds befo ...

P0840 transmission fluid pressure SEN/SW A

P0840 transmission fluid pressure SEN/SW A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds befo ...

Other materials:

Reporting safety defects

For USA

If you believe that your vehicle has a defect which could cause a crash or could

cause injury or death, you should immediately inform the National Highway Traffic

Safety Administration (NHTSA) in addition to notifying NISSAN.

If NHTSA receives similar complaints, it may open an investi ...

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES-1 >> With CONSULT-III: GO TO 2.

YES-2 >> Without CONSULT-III: GO TO 3.

NO >> Go to EC-783, "Diagnosis Procedure".

2.IGNITION SIGNAL FUNCTION ...

U1000 can comm

Description

CAN (Controller Area Network) is a serial communication line for real time

applications. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Modern

vehicle is equipped with many electronic control unit, and eac ...