Nissan Juke Service and Repair Manual : P0078 EVT control solenoid valve

DTC Logic

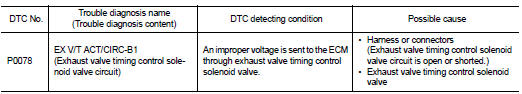

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO2.

2.PERFORM DTC CONFIRMATION PROCED

1. Start engine and let it idle for 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-179, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

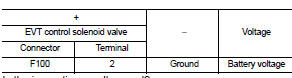

1.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect exhaust valve timing (EVT) control solenoid valve harness connector.

3. Turn ignition switch ON.

4. Check the voltage between exhaust valve timing control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

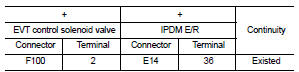

2.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between EVT control solenoid valve harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

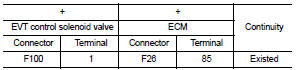

3.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVT control solenoid valve harness connector and ECM harness connector.

4. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE

Check the exhaust valve timing control solenoid valve. Refer to EC-177, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace exhaust valve timing control solenoid valve.

Component Inspection

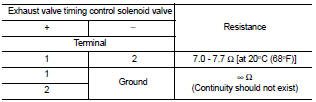

1.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE-I

1. Turn ignition switch OFF.

2. Disconnect exhaust valve timing control solenoid valve harness connector.

3. Check resistance between exhaust valve timing control solenoid valve terminals as per the following.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace exhaust valve timing control solenoid valve. Refer to EM-67, "Exploded View".

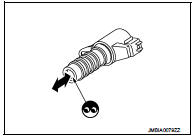

2.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE-II

1. Remove exhaust valve timing control solenoid valve. Refer to EM-67, "Exploded View".

2. Provide 12 V DC between exhaust valve timing control solenoid valve terminals 1 and 2, and then interrupt it. Check that the plunger moves as shown in the figure.

CAUTION: Do not apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in exhaust valve timing control solenoid valve.

NOTE: Always replace O-ring when exhaust valve timing control solenoid valve is removed.

Is the inspection result normal? YES >> INSPECTION END NO >> Replace exhaust valve timing control solenoid valve. Refer to EM-67, "Exploded View".

P0075 IVT control solenoid valve

P0075 IVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P0087, P0088, P0090 FRP control system

P0087, P0088, P0090 FRP control system

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P0087 or P0090 is displayed with DTC P1197, first perform the trouble

diagnosis for DTC

P1197.

• DTC P0087 or P0090 may be displayed when running ou ...

Other materials:

Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger

switch signal, etc.) is transferred via

the CAN communication line.

Component Function Check

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR ...

Parking brake shoe

Exploded View

1. Anti-rattle pin

2. Back plate

3. Toggle lever

4. Parking brake shoe

5. Brake strut

6. Return spring

7. Spring

8. Adjuster

: Apply PBC (Poly Butyl

Cuprysil) grease or silicone-based grease.

Removal and Installation

REMOVAL

WARNING:

Clean any dust from the parkin ...

Direct injection gasoline system

Direct injection gasoline system : System Diagram

Direct injection gasoline system : System Description

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to control the engine system under normal

conditions.

*2: CVT models

*3: M/T models

*4: ECM determines the start signal status by ...