Nissan Juke Service and Repair Manual : Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

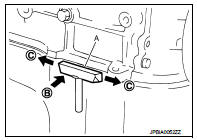

• After removing mounting nuts and bolts, separate the mating surface using the seal cutter [SST: KV10111100 (J-37228)] (A) and remove old liquid gasket sealing.

CAUTION

:

Be careful not to damage the mating surfaces.

• Tap the seal cutter [SST: KV10111100 (J-37228)] to insert it (B), and then slide it (C) by tapping on the side as shown in the figure.

• In areas where the seal cutter [SST: KV10111100 (J-37228)] is difficult to use, lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

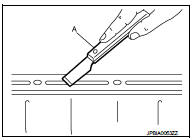

1. Using a scraper (A), remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

• Remove liquid gasket completely from the groove of the liquid gasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove adhering moisture, grease and foreign materials.

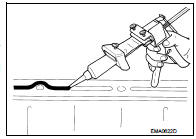

3. Attach liquid gasket tube to the tube presser (commercial service tool). Use Genuine Liquid Gasket or equivalent.

4. Apply liquid gasket without gaps to the specified location according to the specified dimensions.

• If there is a groove for liquid gasket application, apply liquid gasket to the groove.

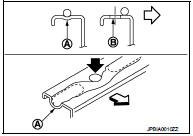

• As for bolt holes (B), normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Check to read the text of this manual.

A : Groove

: Inside

• Within five minutes of liquid gasket application, install the mating component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten mounting bolts or nuts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Parts Requiring Angle Tightening

Parts Requiring Angle Tightening

• Use the angle wrench [SST: KV10112100 (BT8653-A)] for the final tightening

of the following engine parts:

- Camshaft sprocket (INT) bolt

- Cylinder head bolts

- Main bearing cap bolts

- Connec ...

Preparation

Preparation

...

Other materials:

Door request switch

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-DR”, “REQ SW-AS” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Fro ...

Removal and installation

ALTERNATOR

HR16DE

HR16DE : Exploded View

REMOVAL

1. Alternator bracket mounting bolt

2. Alternator bracket

3. Alternator mounting bolt

4. Alternator

5. “B” terminal harness

6. “B” terminal nut

7. Alternator connector

: N·m (kg-m, ft-lb)

DISASSEMBLY

Type: A002TJ1291ZE

1. Rear be ...

Insufficient heating

Description

Symptom

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

Diagnosis Procedure

NOTE:

Perform self-diagnosis with CONSULT-III before performing symptom diagnosis. If

any malfunction result or

DTC is detected, perform the corresponding diagnosis.

1.CHE ...