Nissan Juke Service and Repair Manual : L terminal circuit (short)

Description

The “L” terminal circuit controls the charge warning lamp. The charge warning lamp illuminates when the ignition switch is set to ON or START. When the alternator is providing sufficient voltage with the engine running, the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Diagnosis Procedure

1.CHECK “L” TERMINAL CIRCUIT (SHORT)

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

Does charge warning lamp illuminate? YES >> GO TO 2.

NO >> Refer to CHG-12, "GASOLINE ENGINE MODELS : Work Flow" (gasoline engine models) or CHG-15, "DIESEL ENGINE MODELS : Work Flow" (diesel engine models).

2.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect combination meter connector.

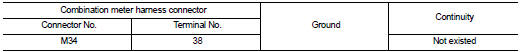

4. Check continuity between combination meter harness connector and ground.

Is the inspection result normal? YES >> Replace combination meter.

NO >> Repair the harness.

L terminal circuit (open)

L terminal circuit (open)

Description

The “L” terminal circuit controls the charge warning lamp. The charge warning

lamp illuminates when the ignition

switch is set to ON or START. When the alternator is providing sufficie ...

S terminal circuit

S terminal circuit

Description

The output voltage of the alternator is controlled by the IC voltage

regulator at the “S” terminal detecting the

input voltage.

The “S” terminal circuit detects the battery voltage ...

Other materials:

Exhaust manifold

Exploded View

1. Stud bolt

2. Exhaust manifold cover

3. Exhaust manifold

4. Gasket

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-11, "Draining".

2. Remo ...

Basic inspection

Work Procedure

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related

malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper con ...

Inspection

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

• Move joint up/down, left/right, and in the axial directions. Check for motion

that is not smooth and for significant

looseness.

• Check boot for cracks, damage, and leakage of grease.

• Check the suppor ...