Nissan Juke Service and Repair Manual : Exhaust manifold

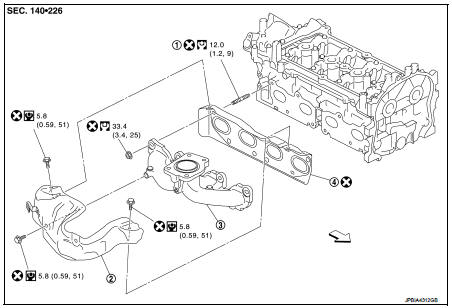

Exploded View

1. Stud bolt

2. Exhaust manifold cover

3. Exhaust manifold

4. Gasket

Engine front

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-11, "Draining".

2. Remove turbocharger. Refer to EM-36, "Exploded View".

3. Remove catalyst convertor. Refer to EM-33, "2WD : Exploded View" (2WD models) or EM-34, "4WD : Exploded View" (4WD models).

4. Remove exhaust manifold cover.

5. Remove exhaust manifold.

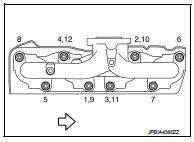

• Loosen nuts in reverse order as shown in the figure.

: Engine front

: Engine front

NOTE:

Disregard the numerical order No. 9 to 12 in removal.

6. Remove gasket.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSTALLATION

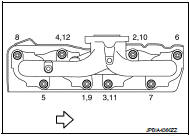

1. Install gasket to cylinder head as shown in the figure.

: Engine front

: Engine front

2. Install exhaust manifold with the following procedure: a. Tighten nuts in numerical order as shown in the figure.

: Engine front

: Engine front

NOTE

:

• Tighten nuts the No.1 to No.4 in two steps.

• The numerical order No.9 to No.12 shows the second step.

3. Install remaining parts in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

Surface Distortion

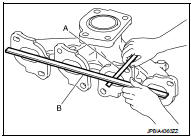

• Using feeler gauge (A) and straightedge (B), check the surface distortion

of exhaust manifold mating surface in each exhaust port

and entire part.

Limit : Refer to EM-130, "Exhaust Manifold".

• If it exceeds the limit, replace exhaust manifold.

Turbocharger

Turbocharger

Exploded View

1. Heat insulator

2. Actuator hose

3. Clamp

4. Turbocharger inlet tube

5. Gasket

6. Gasket

7. Clamp

8. Oil outlet hose

9. Oil return pipe

10. Oil supply tube

11. O-ri ...

Oil pan (lower)

Oil pan (lower)

Exploded View

1. O-ring

2. Oil pan (upper)

3. Oil level gauge guide

4. O-ring

5. Oil level gauge

6. Oil pump drive chain

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump chain ...

Other materials:

Headlamp washer circuit

Component Function Check

1.CHECK HEADLAMP WASHER OPERATION

CONSULT-III ACTIVE TEST

1. Select “HEAD LAMP WASHER” of IPDM E/R active test item.

2. With operating the test item, check headlamp operation.

On :Headlamp washer ON operation

Off :Stop the headlamp washer.

Is headlamp washer operation ...

Line pressure test

Work Procedure

INSPECTION

1. Check the engine oil level. Replenish if necessary. LU-25, "Inspection".

2. Check for leak of the CVT fluid. Refer to TM-480, "Inspection".

3. Drive for about 10 minutes to warm up the vehicle so that the CVT fluid

temperature is 50 to 80°C (122 ...

Camshaft

*: Total indicator readin

VALVE LIFTER

VALVE CLEARANCE

*: Approximately 80°C (176°F)

AVAILABLE VALVE LIFTER

...