Nissan Juke Service and Repair Manual : Evaporative emission system

Inspection

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections, chafing and deterioration.

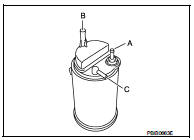

2. Check EVAP canister as follows: a. Block port (B). Orally blow air through port (A).

Check that air flows freely through port (C).

b. Block port (A). Orally blow air through port (B).

Check that air flows freely through port (C).

3. Visually inspect the fuel check valve for cracks, damage, loose connections chafing and deterioration.

4. Check fuel check valve as follows: a. Blow air through connector on the fuel tank side. A considerable resistance should be felt and a portion of air flow should be directed toward the EVAP canister side.

b. Blow air through connector on EVAP canister side. Air flow should be smoothly directed toward fuel tank side.

c. If fuel check valve is suspected or not properly functioning in step 1 and 2 above, replace it.

5. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

a. Wipe clean valve housing.

b. Check valve opening pressure and vacuum.

Pressure:

15.3 - 20.0 kPa (0.153 - 0.200 bar, 0.156 - 0.204 kg/

cm2, 2.22 - 2.90 psi)

Vacuum:

–6.0 to –3.4 kPa (–0.06 bar to –-0.034bar, –0.061 to –

0.035 kg/cm2, –0.87 to –0.49 psi)

c. If out of specification, replace fuel filler cap as an assembly

Ignition timing

Ignition timing

Description

This describes how to check the ignition timing. For the actual procedure,

follow the instructions in “BASIC

INSPECTION”.

Special Repair Requirement

1.CHECK IGNITION TIMING

1. Attac ...

Positive crankcase ventilation

Positive crankcase ventilation

Inspection

1.CHECK PCV VALVE

With engine running at idle, remove PCV valve from rocker cover. A

properly working valve makes a hissing noise as air passes through

it. A strong vacuum should be fel ...

Other materials:

ABS branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit

(control unit) for damage, bend

and loose connection (unit side and connector side).

...

Rear shock absorber

Exploded View

1. Rear suspension beam

2. Shock absorber

3. Bound bumper

4. Bound bumper cover

5. Washer

6. Bushing

7. Distance tube

8. Piston rod lock nut

9. Cap

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Re ...

Does not operate

Description

ABS function and EBD function does not operate.

Diagnosis Procedure

CAUTION:

ABS function and EBD function never operate when the vehicle speed is 10 km/h

(6.2 MPH) or less.

1.CHECK ABS WARNING LAMP

Check that ABS warning lamp and brake warning lamp turn ON and turn OFF

appro ...