Nissan Juke Service and Repair Manual : Evap canister

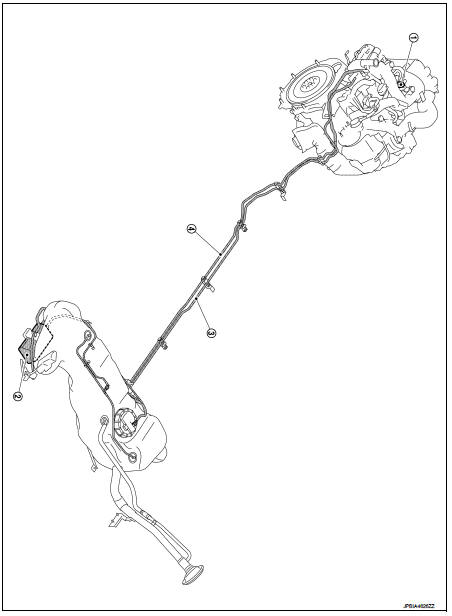

2WD : Hydraulic Layout

EVAPORATIVE EMISSION LINE DRAWING

1.EVAP canister purge volume control

solenoid valve

2. EVAP canister

3. EAVP line

4. Fuel line

NOTE

:

Do not use soapy water or any type of solvent while installing vacuum hose or

purge hoses.

2WD : Removal and Installation

REMOVAL

1. Disconnect EVAP canister hoses.

2. Remove EVAP canister fixing bolt.

3. Remove EVAP canister.

INSTALLATION

Install in the reverse order of removal.

NOTE

:

Tighten EVAP canister fixing bolt to the specified torque.

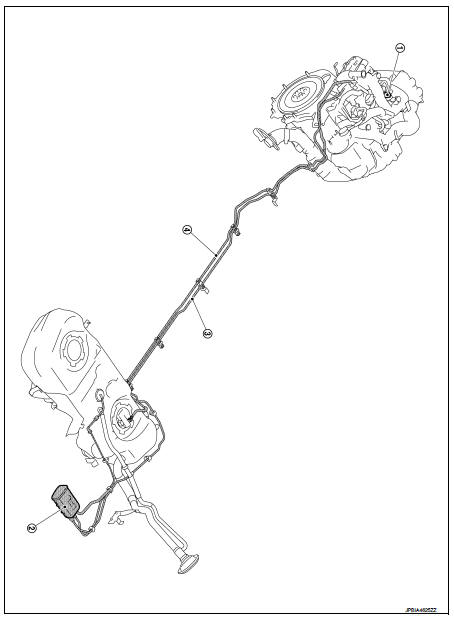

4WD : Hydraulic Layout

EVAPORATIVE EMISSION LINE DRAWING

1. EVAP service port

2. EVAP canister

3. EVAP line

4. Fuel line

NOTE

:

Do not use soapy water or any type of solvent while installing vacuum hose or

purge hoses.

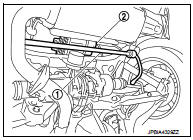

4WD : Removal and Installation

REMOVAL

1. Remove rear stabilizer (1). Refer to RSU-34, "Exploded View".

2. Disconnect EVAP canister hoses.

3. Remove EVAP canister fixing bolt.

4. Remove EVAP canister (2).

INSTALLATION

Install in the reverse order of removal.

NOTE

:

Tighten EVAP canister fixing bolt to the specified torque.

Fuel tank

Fuel tank

2WD : Exploded View

1. Fuel filler cap

2. Grommet

3. Fuel filler tube

4. EVAP canister hose

5. Fuel tank mounting band (RH)

6. Fuel tank mounting band (LH)

7. Fuel tank

8. Clamp

9. Fu ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Fuel Tank

Standard and Limit

...

Other materials:

U1010 control unit (CAN)

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...

U1001 Can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each c ...

Parts Requiring Angle Tightening

Х Use the angle wrench [SST: KV10112100] for the final tightening of the

following engine parts:

- Camshaft sprocket (INT) bolt

- Cylinder head bolts

- Main bearing cap bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No the angle wrench is required as bolt flange is

provided with ...