Nissan Juke Service and Repair Manual : Engine stand setting

NOTE

:

Explained here is how to disassemble with engine stand supporting transaxle

surface. When using different

type of engine stand, note with difference in steps and etc.

1. Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the engine. Refer to EM-215, "Exploded View".

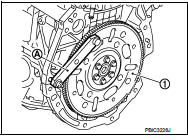

2. Install engine to engine stand with the following procedure: a. Remove flywheel or drive plate.

• Secure flywheel (1) with a stopper plate [SST: KV11105210] (A), and remove mounting bolts (M/T models).

![• Secure driveplate (1) with a stopper plate [SST: KV11105210]](images/books/335/5/index.127.jpg)

• Secure driveplate (1) with a stopper plate [SST: KV11105210] (A), and remove mounting bolts (CVT models).

CAUTION:

• Never disassemble them.

• Never place them with signal plate facing down.

• When handling signal plate, take care not to damage or scratch them.

• Handle signal plate in a manner that prevents them from becoming magnetized.

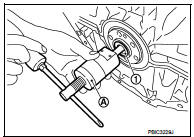

b. Remove pilot converter (1) from the rear end of the crankshaft.

Use a pilot bush puller [SST: ST16610000] (A), if necessary.

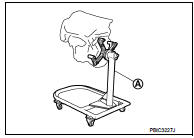

c. Lift the engine with a hoist to install it onto widely use engine stand.

CAUTION

:

• Use the engine stand that has a load capacity [approximately 150 kg (331

lb) or more] large

enough for supporting the engine weight.

• If the load capacity of stand is not adequate, remove the following parts beforehand to reduce the potential risk of overturning stand.

- Intake manifold: Refer to EM-163, "Exploded View".

- Exhaust manifold: Refer to EM-166, "Removal and Installation".

- Rocker cover: Refer to EM-178, "Exploded View".

NOTE

:

The figure shows an example of widely used engine stand (A)

that can support mating surface of transaxle with flywheel

removed.

CAUTION:

Before removing the hanging chains, check the engine

stand is stable and there is no risk of overturning.

3. Drain engine oil. Refer to LU-26, "Draining".

CAUTION:

Be sure to clean drain plug and install with new drain plug washer.

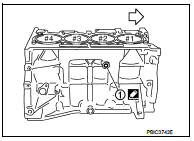

4. Drain engine coolant by removing water drain plug (1) from inside of the engine.

: Engine front

: Engine front

Tightening torque : Refer to EM-227, "Exploded View".

Use Genuine Liquid Gasket or equivalent.

Engine unit

Engine unit

Disassembly

1. Remove intake manifold. Refer to EM-163, "Exploded View".

2. Remove exhaust manifold. Refer to EM-166, "Exploded View".

3. Remove oil pan (lower). Refer to EM-16 ...

Other materials:

Drive pinion

Exploded View

1. Pinion lock nut

2. Companion flange

3. Drive pion oil seal

4. Pinon rear bearing

5. Transfer case

6. Gasket

7. Filler plug

8. Collapsible spacer

9. Drive pinion adjust shim

10. Drive pinion

11. Pinion front bearing

12. Ring gear

13. Ring gear shaft

14. Ring ...

B1033, B1034 crash zone sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Off-road recovery

If the right side or left side wheels leave the road surface, maintain control

of the vehicle by following the procedure below. Please note that this procedure

is only a general guide. The vehicle must be driven as appropriate based on the

conditions of the vehicle, road and traffic.

1. Remai ...