Nissan Juke Service and Repair Manual : Door switch

Component Function Check

1.CHECK FUNCTION

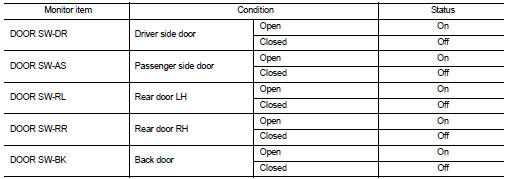

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR SW-DR”, “DOOR SW-AS”, “DOOR SW-RL”, “DOOR SW-RR”, “DOOR SW-BK” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door switch is OK.

NO >> Refer to DLK-258, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK DOOR SWITCH INPUT SIGNAL

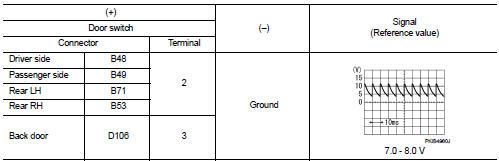

1. Turn ignition switch OFF.

2. Disconnect malfunctioning door switch connector.

3. Check signal between malfunctioning door switch harness connector and ground using oscilloscope.

Is the inspection result normal? YES-1 >> Back door: GO TO 3.

YES-2 >> Other door: GO TO 4.

NO >> GO TO 2.

2.CHECK DOOR SWITCH CIRCUIT

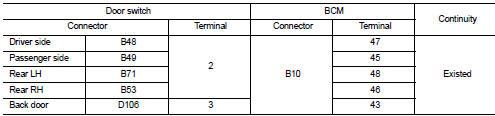

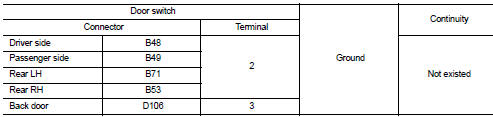

1. Disconnect BCM connector.

2. Check continuity between door switch harness connector and BCM harness connector.

3. Check continuity between door switch harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

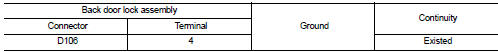

3.CHECK BACK DOOR SWITCH CIRCUIT

Check continuity between back door lock assembly harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK DOOR SWITCH

Refer to DLK-259, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace malfunctioning door switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

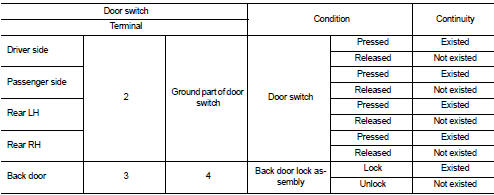

1.CHECK DOOR SWITCH

1. Turn ignition switch OFF.

2. Disconnect malfunctioning door switch connector.

3. Check continuity between door switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunction door switch.

Door request switch

Door request switch

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-DR”, “REQ SW-AS” in “DATA MONITOR” mode.

3. Check that the function operates nor ...

Hazard function

Hazard function

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “FLASHER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according ...

Other materials:

Turn signal lamp circuit

Component Function Check

1.CHECK TURN SIGNAL LAMP

CONSULT-III ACTIVE TEST

1. Select “FLASHER” of BCM (FLASHER) active test item.

2. With operating the test items, check that the turn signal lamps is turned ON.

LH : Turn signal lamps (LH) ON

RH : Turn signal lamps (RH) ON

Off : Turn signal lam ...

Engine knock

Description

CHART 16: ENGINE KNOCK

Diagnosis Procedure

1.CHECK ENGINE OIL

Check the grade of engine oil. Refer to LU-33, "Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace engine oil. Refer to LU-34, "Refilling".

2.CHECK ENGINE ...

Air breather hose

Removal and Installation

REMOVAL

1. Remove clip from bracket.

2. Remove air breather hose from transaxle assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Check that air breather hose is not collapsed or blocked due to folding or

bending ...