Nissan Juke Service and Repair Manual : Diagnosis and repair workflow

Work Flow

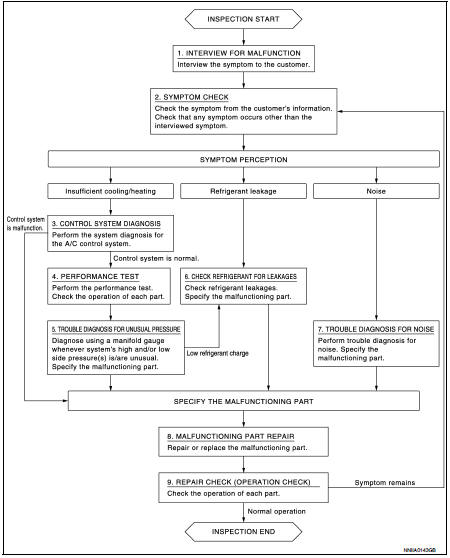

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information. Check that any symptom occurs other than the interviewed symptom.

Insufficient cooling/heating>>GO TO 3.

Refrigerant leakage>>GO TO 6.

Noise >> GO TO 7.

3.CONTROL SYSTEM DIAGNOSIS

Perform the system diagnosis for the A/C control system.

• Refer to HAC-135, "Work Flow". (AUTOMATIC AIR CONDITIONING) • Refer to HAC-271, "Work Flow". (MANUAL AIR CONDITIONING) • Refer to HAC-322, "Work Flow". (MANUAL HEATER)

Is A/C control system normal? YES >> GO TO 4.

NO >> GO TO 8.

4.PERFORMANCE TEST

Perform the performance test. Check the operation of each part. Refer to HA-26, "Inspection".

>> GO TO 5.

5.TROUBLE DIAGNOSIS FOR UNUSUAL PRESSURE

Diagnose using a manifold gauge whenever system's high and/or low side pressure(s) is/are unusual. Specify the malfunctioning part. Refer to HA-28, "Symptom Table".

Low refrigerant charge>>GO TO 6.

Except above>>GO TO 8.

6.CHECK REFRIGERANT FOR LEAKAGES

Check refrigerant for leakages. Specify the malfunctioning part. Refer to HA-19, "Leak Test".

>> GO TO 8.

7.TROUBLE DIAGNOSIS FOR NOISE

Perform trouble diagnosis for noise. Specify the malfunctioning part. Refer to HA-28, "Symptom Table".

>> GO TO 8.

8.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 9.

9.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> INSPECTION END

NO >> GO TO 2.

Basic inspection

Basic inspection

...

Refrigerant

Refrigerant

Description

CONNECTION OF SERVICE TOOLS AND EQUIPMENT

1. Shut-off valve

2. A/C service valve

3. Recovery/recycling/recharging

equipment

4. Vacuum pump

5. Manifold gauge set

6. Refrigerant ...

Other materials:

General Precautions

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a ???CAUTION: FLAMMABLE??? sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO2 fire

extinguisher.

• Never smoke while servicing fuel system. Keep open flames and spa ...

Power supply and ground circuit

A/C auto AMP. : Diagnosis Procedure

1.CHECK SYMPTOM

Check symptom (A or B).

Which symptom is detected?

A >> GO TO 2.

B >> GO TO 5.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10A fuse (No. 3).

NOTE:

Refer to PG-23, "Fuse and Fusible Link Arrangement".

...

Parking brake shoe

Adjustment

1. Adjust parking brake lever stroke. Refer to PB-2, "Inspection and

Adjustment".

2. Perform parking brake break-in (drag on) operation by driving vehicle under

the following conditions:

• Drive forward

• Vehicle speed: Approx. 43 km/h (27 MPH) set (constant and forward) ...