Nissan Juke Service and Repair Manual : CVT position

Inspection and Adjustment

INSPECTION

1. Turn ON the ignition switch with the selector lever at the P position.

2. Press the selector button with the brake pedal depressed, and confirm that the lever can be shifted to positions other than P. Also confirm that shifting is not allowed from the P position to other position without depressing the brake pedal.

3. Move the selector lever and check for “excessive effort”, “sticking”, “noise” or “rattle”.

4. Confirm that selector lever stops at each position with the feel of engagement when it is moved through all the positions. Check whether or not the actual position the selector lever is in matches the position shown by the transaxle body.

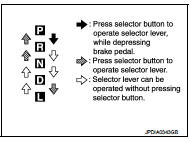

5. Make sure that the selector lever is shifted to all the shift positions in the manner shown in the figure.

6. When the selector button is pressed without applying forward/ backward force to the selector lever at “P”, “R”, “N” and “D” positions, there should be no “sticking” on the button operation.

7. The reverse lamp lights and the reverse warning buzzer sounds at the “R” position and the reverse lamp does not light and the reverse warning buzzer does not sound at other positions. Confirm that the buzzer does not sound when selector lever is in the “P” or “N” position, in particular, with the lever pushed against the “R” position.

8. Check that the engine can be started with the selector lever in the “P” and “N” positions only.

9. Check that the transaxle is locked when the selector lever is in the P position.

ADJUSTMENT

1. Shift the selector lever to the “P” position.

CAUTION:

Rotate the wheels at least a quarter turn and be certain the Park position

mechanism is fully

engaged.

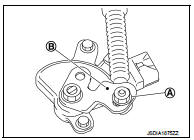

2. Remove nut (A) and set manual lever (B) to the “P” position.

CAUTION:

Do not apply force to the manual lever.

3. Tighten nuts to the specified torque. Refer to TM-485, "Exploded View".

CAUTION:

In tightening, fix the manual lever.

Line pressure test

Line pressure test

Work Procedure

INSPECTION

1. Check the engine oil level. Replenish if necessary. LU-25, "Inspection".

2. Check for leak of the CVT fluid. Refer to TM-480, "Inspection".

3. Driv ...

Other materials:

Wiring diagram

BCM

LHD

LHD : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

RHD

RHD : Wiring Diagram

For con ...

Periodic maintenance

REAR WHEEL HUB

Inspection

COMPONENT PART

Check the mounting conditions (looseness, back lash) of each component and

component conditions (wear,

damage) are normal.

WHEEL HUB ASSEMBLY (BEARING-INTEGRATED TYPE)

Check the following items, and replace the part it necessary.

• Move wheel hub ...

Engine overheating

Description

CHART 17: ENGINE OVERHEATING

Diagnosis Procedure

1.CHECK COOLING SYSTEM

Check the cooling system. Refer to CO-60, "Troubleshooting Chart".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace.

2.CHECK ECM POWER SUPPLY AND GROUND CIR ...