Nissan Juke Service and Repair Manual : Back door opener switch

Component Function Check

1.CHECK FUNCTION

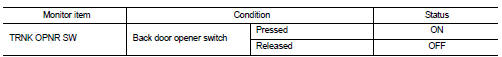

1. Select “TRUNK” of “BCM” using CONSULT-III.

2. Select “TRNK OPNR SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Back door opener switch is OK.

NO >> Refer to DLK-513, "Diagnosis Procedure".

Diagnosis Procedure

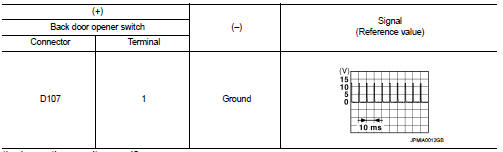

1.CHECK BACK DOOR OPEN INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

3. Check signal between back door opener switch harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

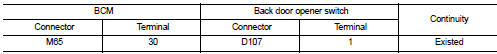

2.CHECK BACK DOOR OPENER SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and back door opener switch harness connector.

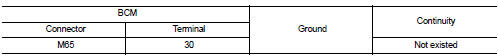

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-161, "Removal and Installation".

NO >> Repair or replace harness.

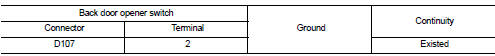

3.CHECK BACK DOOR OPENER SWITCH GROUND CIRCUIT

Check continuity between back door opener switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK BACK DOOR OPENER SWITCH

Refer to DLK-514, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace back door opener switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

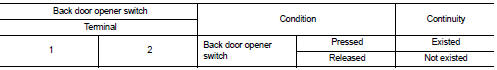

1.CHECK BACK DOOR OPENER SWITCH

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

3. Check continuity between back door opener switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace back door opener switch.

Back door opener actuator

Back door opener actuator

Diagnosis Procedure

1.CHECK BACK DOOR OPENER ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect back door opener assembly connector.

3. Check voltage between back door opener assembl ...

Door lock actuator

Door lock actuator

Driver side

DRIVER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function opera ...

Other materials:

Shift position indicator circuit

Component Parts Function Inspection

1.CHECK SHIFT POSITION INDICATOR

1. Start the engine.

2. Shift selector lever.

3. Check that the selector lever position and the shift position indicator on

the combination meter are identical.

Is the inspection result normal?

YES >> INSPECTION END ...

Periodic maintenance

REAR PROPELLER SHAFT

Inspection

APPEARANCE AND NOISE

• Check the propeller shaft tube surface for dents or cracks. If damaged,

replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, inspe ...

Rear suspension assembly

Exploded View

1. Rear suspension member

2. Rebound stopper

3. Washer

: Vehicle front

N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Remove center pipe. Refer to EX-6, "Removal and Installation".

3. ...