Nissan Juke Service and Repair Manual : Wheel alignment

Inspection

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE

:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full.

Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

• Tires for improper air pressure and wear

• Road wheels for runout: refer to WT-7, "Inspection".

• Wheel bearing axial end play: refer to RAX-4, "Inspection".

• Shock absorber operation

• Each mounting point of axle and suspension for looseness and deformation

• Each of rear suspension beam and shock absorber for cracks, deformation, and

other damage

• Vehicle height (posture)

CAMBER

• Measure camber of both right and left wheels with a suitable alignment gauge.

• If camber is outside specified range, replace rear suspension beam. Refer to RSU-13, "Exploded View".

Camber : Refer to RSU-15, "Wheel Alignment".

TOE-IN

Measure toe-in by the following procedure.

WARNING:

• Always perform the following procedure on a flat surface.

• Check that no person is in front of vehicle before pushing it.

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

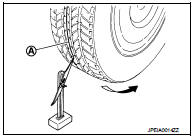

3. Put matching mark (A) on base line of the tread (rear side) of both tires at the same height of hub center. These are measuring points.

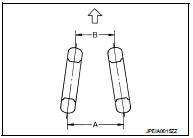

4. Measure distance (A) (rear side).

: Vehicle front

5. Push vehicle slowly ahead to rotate wheels 180 degrees (1/2 turn).

NOTE

:

If the wheels rotates more than 180 degrees (1/2 turn), start this

procedure again from the beginning. Do not push the vehicle

backward.

6. Measure distance (B) (front side).

Total toe-in = A − B Total toe-in : Refer to RSU-15, "Wheel Alignment".

• If toe-in is outside specified range, replace rear suspension beam. Refer to RSU-13, "Exploded View".

Rear suspension assembly

Rear suspension assembly

Inspection

COMPONENT PART

Check the mounting conditions (looseness, backlash) of each component and

component conditions (wear,

damage) are normal.

SHOCK ABSORBER ASSEMBLY

Check for oil leaka ...

Other materials:

Hazard reminder operation does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-141, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&q ...

P0011 IVT control

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0011 is displayed with DTC P0075, first perform the trouble diagnosis

for EC-307, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following proc ...

License plate lamp

Exploded View

1. License plate lamp housing assembly

2. Blub

3. License plate lamp blub socket

: Pawl

Removal and Installation

CAUTION:

Disconnect battery negative terminal or remove the fuse.

REMOVAL

1. While pressing the license plate lamp to direction right side, pull

it to directio ...