Nissan Juke Service and Repair Manual : Vacuum pump

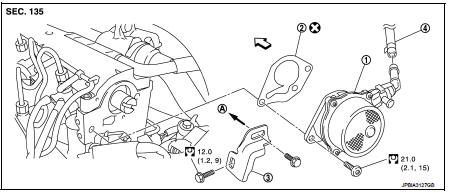

Exploded View

1. Vacuum pump

2. Gasket

3. Damper valve bracket

4. Vacuum hose

A. To electric throttle control actuator

Engine front

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-280, "Exploded View".

2. Disconnect vacuum hose from vacuum pump side.

3. Remove damper valve bracket.

4. Remove vacuum pump.

INSTALLATION

Install in the reverse order of removal.

Inspection

INSPECTION BEFORE REMOVAL

1. Disconnect vacuum hose, and connect a vacuum gauge via 3-way connector.

• Disconnect point where vacuum from vacuum pump can be measured directly and install 3-way connector.

2. Start engine and measure generated vacuum at idle speed.

Standard : -86.6 to -101.3 kPa (-866 to -1,013 mbar, -650 to -760 mmHg, -25.59 to -29.92 inHg)

Glow plug

Glow plug

Exploded View

1. Glow plug

Engine front

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

CAUTION:

Remove glow plug only if necessary. If carbon adheres, it may be stuck and

broken.

1. ...

Injection tube and fuel injector

Injection tube and fuel injector

Exploded View

1. Spill hose

2. Injection tube

3. Fuel injector

4. Heat protection washer

5. Fuel injector bracket

6. Fuel injector bracket spacer

7. Fuel rail stud bolt

8. Fuel rail

9 ...

Other materials:

Light & rain sensor

Component Function Check

1.CHECK FRONT WIPER AUTO OPERATION

1. Clean rain sensor detection area of windshield fully.

2. When the front wiper switch is turned to AUTO position, front wiper operates

once regardless of a rainy

condition.

Is front wiper (AUTO) operation normally?

YES >> ...

P0848 transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, the ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With ...

Precaution for Harness Repair

• Solder the repair part, and wrap it with tape. [Twisted wire fray

must be 110 mm (4.33 in) or less.]

• Never bypass the repair point with wire. (If it is bypassed, the turnout

point cannot be separated and the twisted wire characteristics

are lost.)

...