Nissan Juke Service and Repair Manual : Vacuum lines

MR16DDT : Removal and Installation

REMOVAL

1. Remove the vacuum hose and vacuum piping.

2. Perform inspection after removal. Refer to BR-115, "MR16DDT : Inspection".

INSTALLATION

Note the following, install the vacuum hose.

• When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown in the figure.

CAUTION:

Never use lubricating oil during assembly.

A : 24 mm (0.95 in) or more

- Face the paint mark of vacuum hose (engine side) upward to assemble.

- Face the paint mark of vacuum hose (brake booster side) to the vehicle front side to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR- 115, "MR16DDT : Exploded View".

MR16DDT : Inspection

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

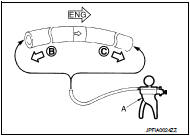

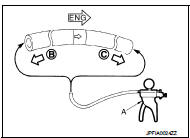

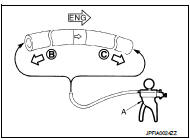

Check Valve Airtightness • Use a handy vacuum pump (A) to check.

When connected to the booster side (B): Vacuum should decrease within 1.3 kPa (9.8 mmHg, 0.38 inHg, 0.013 bar) for 15 seconds under a vacuum of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C): Vacuum should not exist.

• Replace vacuum hose if vacuum hose is malfunctioning.

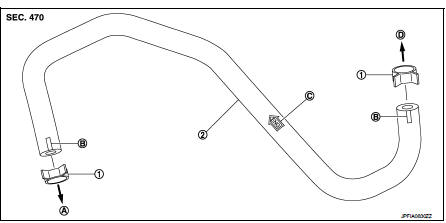

HR16DE : Exploded View

1. Clamp

2. Vacuum hose (built-in check valve)

A. To intake manifold

B. Paint mark

C. Stamp indicating engine direction

D. To brake booster

HR16DE : Removal and Installation

REMOVAL

1. Remove the vacuum hose and vacuum piping.

2. Perform inspection after removal. Refer to BR-117, "HR16DE : Inspection".

INSTALLATION

Note the following, install the vacuum hose.

• When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown in the figure.

CAUTION:

Never use lubricating oil during assembly.

A : 24 mm (0.95 in) or more

- Face the paint marks upward to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR- 116, "HR16DE : Exploded View".

HR16DE : Inspection

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness • Use a handy vacuum pump (A) to check.

When connected to the booster side (B): Vacuum should decrease within 1.3 kPa (9.8 mmHg, 0.38 inHg, 0.013 bar) for 15 seconds under a vacuum of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C): Vacuum should not exist.

• Replace vacuum hose assembly if vacuum hose and check valve are malfunctioning.

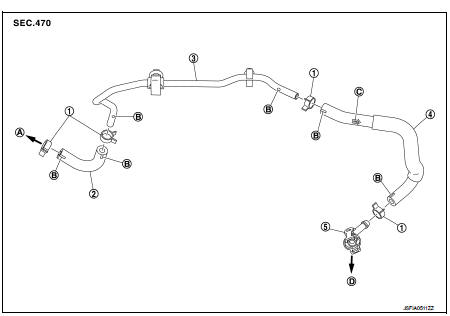

K9K : Exploded View

1. Clamp

2. Vacuum hose

3. Vacuum piping

4. Vacuum hose (built-in check valve)

5. Connector

A. To brake booster

B. Paint mark

C. Stamp indicating engine direction

D. To vacuum pump

K9K : Removal and Installation

REMOVAL

1. Remove air duct and air cleaner case. Refer to EM-280, "Removal and Installation".

2. Remove the vacuum hose and connector.

INSTALLATION

Note the following, install the vacuum hose.

• When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown in the figure.

CAUTION:

Never use lubricating oil during assembly.

A : 24 mm (0.95 in) or more

- Face the paint mark of vacuum hose (built-in check valve, connector side) upward to assemble.

- Face the other paint marks to vehicle front side to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR- 117, "K9K : Exploded View".

K9K : Inspection

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness • Use a handy vacuum pump (A) to check.

When connected to the booster side (B): Vacuum should decrease within 1.3 kPa (9.8 mmHg, 0.38 inHg, 0.013 bar) for 15 seconds under a vacuum of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C): Vacuum should not exist.

• Replace vacuum hose assembly if vacuum hose and check valve are malfunctioning.

Brake booster

Brake booster

Exploded View

2WD

MR16DDT, HR16DE

1. Master cylinder assembly

2. Vacuum pipe

3. Brake booster

4. Lock nut

5. Clevis

6. Gasket

: N·m (kg-m, ft-lb)

K9K

1. Master cylinder assembly

2 ...

Front disc brake

Front disc brake

Brake pad : Exploded View

MR16DDT

1. Cylinder body

2. Inner shim

3. Inner pad (with pad wear sensor)

4. Pad retainer

5. Torque member

6. Outer pad

7. Outer shim

1: Apply MOLYKOTE® AS880 ...

Other materials:

P2122, P2123 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2122 or P2123 is displayed with DTC P0643, first perform the trouble

diagnosis for DTC P0643.

Refer to EC-686, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, alw ...

P0847 transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With ...

Refilling

1. Install reservoir tank if removed and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

Radiator drain plug : Refer to CO-42, "Exploded View".

• If water drain plugs on cylinder block are removed, close and tighten them.

Refer to EM-228, &quo ...