Nissan Juke Service and Repair Manual : Stop lamp switch

Component Function Check

1.CHECK STOP LAMP SWITCH OPERATION

Depress brake pedal and check that stop lamp turns ON, or release brake pedal and check stop lamp turns OFF.

Is the inspection result normal? YES >> GO TO 2.

NO >> Check stop lamp system. Refer to EXL-39, "Wiring Diagram".

2.CHECK DATA MONITOR

With CONSULT-III.

1. Turn the ignition switch OFF to ON.

2. Select “ABS”, “DATA MONITOR” and “STOP LAMP SW” according to this order. Check that data monitor displays “On” or “Off” when brake pedal is depress or release. Refer to BRC-27, "Reference Value".

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to BRC-67, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK STOP LAMP SWITCH CLEARANCE

1. Turn the ignition switch OFF.

2. Check stop lamp clearance.

- LHD: Refer to BR-9, "Inspection and Adjustment".

- RHD: Refer to BR-77, "Inspection and Adjustment".

Is the inspection result normal? YES >> GO TO 2.

NO >> Adjust stop lamp switch clearance.

• LHD: Refer to BR-9, "Inspection and Adjustment".

• RHD: Refer to BR-77, "Inspection and Adjustment".

2.CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to BRC-68, "Component Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace stop lamp switch.

• LHD: Refer to BR-21, "Removal and Installation".

• RHD: Refer to BR-89, "Removal and Installation".

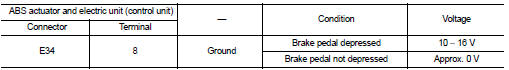

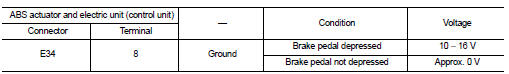

3.CHECK STOP LAMP SWITCH CIRCUIT (1)

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

4. Turn the ignition switch ON.

CAUTION:

Never start engine.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 4.

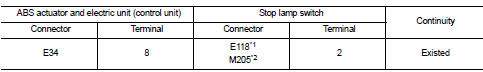

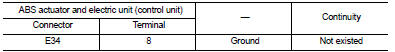

4.CHECK STOP LAMP SWITCH CIRCUIT (2)

1. Turn the ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity between ABS actuator and electric unit (control unit) harness connector and stop lamp switch harness connector.

*1: LHD

*2: RHD

4. Check continuity between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Check 10 A fuse (#38).

2. Check continuity and short circuit between stop lamp switch harness connector terminal (1) and 10 A fuse (#38).

Is the inspection result normal? YES >> Perform trouble diagnosis for battery power supply. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

6.CHECK TERMINAL

• Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

• Check stop lamp switch pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-90, "Removal and Installation".

NO >> Repair or replace error-detected parts.

Component Inspection

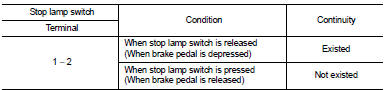

1.CHECK STOP LAMP SWITCH

1. Turn the ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity when stop lamp switch is operated.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace stop lamp switch.

• LHD: Refer to BR-21, "Removal and Installation".

• RHD: Refer to BR-89, "Removal and Installation".

Power supply and ground circuit

Power supply and ground circuit

Diagnosis Procedure

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER

SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harnes ...

Parking brake switch

Parking brake switch

Component Function Check

1.CHECK PARKING BRAKE SWITCH OPERATION

Operate the parking brake lever. Then check that the brake warning lamp in

the combination meter turns ON/

OFF correctly.

Is the ...

Other materials:

P0090 fuel pump

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK HIGH PRESSURE SUPPLY PUMP (PRESSURE CONTROL VALVE) POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect high pressure supply pump (pressure control valve) harness

connector.

3. Turn ignition switch ON.

4. Check the voltage betwe ...

P1705 TP sensor

Description

Electric throttle control actuator consists of throttle control motor,

accelerator pedal position sensor, throttle

position sensor etc. The actuator sends a signal to the ECM, and ECM sends the

signal to TCM with CAN

communication.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATI ...

Integrated control system (if so equipped)

The Integrated Control System is located below the audio system or navigation

system (if so equipped). Two Integrated Control System modes can be selected: Drive

mode and Climate Control mode.

Depending on which Integrated Control System mode selected (Drive mode or Climate

Control mode), the ...