Nissan Juke Service and Repair Manual : Speed limiter main switch

Component Function Check

1.CHECK SPEED LIMITER MAIN SWITCH FUNCTION

1. Turn ignition switch ON.

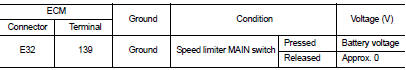

2. Check the voltage between ECM harness connector terminals under the following conditions

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-1020, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK SPEED LIMITER MAIN SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination switch (spiral cable) harness connector.

3. Turn ignition switch ON.

4. Check voltage between combination switch (spiral cable) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Combination switch (spiral cable)

• 10 A fuse (No. 2)

• Harness for open and short between combination switch (spiral cable) and

ground.

>> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK SPEED LIMITER MAIN SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

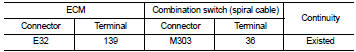

3. Check the continuity between ECM harness connector and combination switch (spiral cable) harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Harness connector E105, M77 • Combination switch (spiral cable) • Harness for open and short between ECM and combination switch (spiral cable)

>> Repair open circuit, short to ground or short to power in harness or connectors.

6.CHECK ASCD STEERING SWITCH

Refer to EC-1021, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace ASCD steering switch.

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

>> INSPECTION END

Component Inspection

1.CHECK ASCD STEERING SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect combination switch (spiral cable) harness connector.

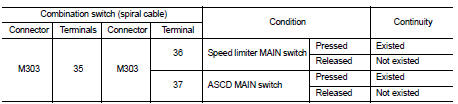

3. Check the continuity between combination switch (spiral cable) harness connector terminals under the following condition.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace ASCD steering switch.

2.CHECK ASCD STEERING SWITCH-II

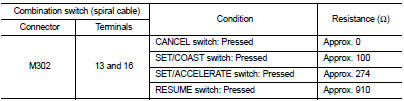

Check resistance between combination switch (spiral cable) harness connector terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace ASCD steering switch.

Malfunction indicator

Malfunction indicator

Component Function Check

1.CHECK MI FUNCTION

1. Turn ignition switch ON.

2. Make sure that MI lights up.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-1019, ...

Other materials:

Diagnosis system [ABS actuator and electric unit (control

unit)]

CONSULT-III Function

APPLICATION ITEMS

CONSULT-III can display each diagnostic item using the diagnostic test modes

as follows.

*: The following diagnosis information is erased by erasing.

• DTC

• Freeze frame data (FFD)

ECU IDENTIFICATION

ABS actuator and electric unit (control unit) p ...

Precautions on cruise control

• If the cruise control system malfunctions, it will cancel automatically.

The CRUISE indicator light on the meter panel will then blink to warn the driver.

• If the engine coolant temperature becomes excessively high, the cruise control

system will cancel automatically.

• If ...

Rear door

Exploded View

1. Rear door panel

2. TORX bolt

3. Door striker

4. Door check link

5. Door hinge (lower)

6. Door hinge (upper)

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: Body grease

Door assembly

DOOR ASSEMBLY : Removal and Installation

CAUTION:

• Perform work with 2 ...