Nissan Juke Service and Repair Manual : Reverse idler shaft and gear

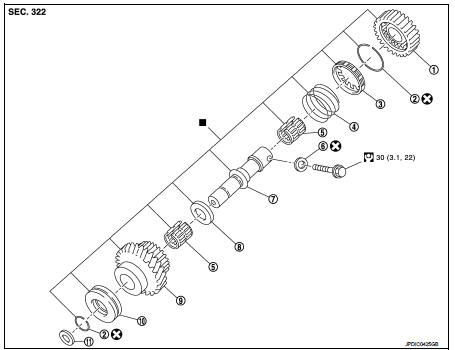

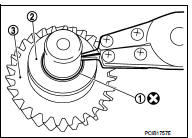

Exploded View

1. Reverse output gear

2. Snap ring

3. Reverse baulk ring

4. Return spring

5. Needle bearing

6. Seal washer

7. Reverse idler shaft

8. Spacer

9. Reverse input gear

10. Lock washer

11. Spring washer

: Replace the parts as a set.

: Replace the parts as a set.

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Disassembly

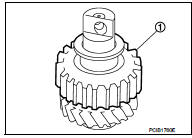

1. Remove reverse output gear (1).

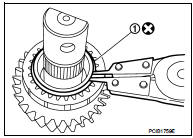

2. Remove snap ring (1).

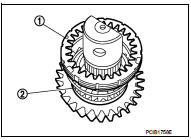

3. Remove reverse baulk ring (1) and return spring (2).

4. Remove snap ring (1), lock washer (2), and reverse input gear (3).

5. Remove needle bearings (1) and washer.

Assembly

Note the following procedures, and assemble in the reverse order of disassembly.

CAUTION:

• Never reuse snap ring.

• Check that snap ring is securely installed in a groove.

• Replace reverse output gear, snap ring, reverse baulk ring, return spring, needle bearing, reverse idler shaft, spacer, reverse input gear, and lock washer as a set.

Inspection

INSPECTION AFTER DISASSEMBLY

Shaft and Gear

Check the following items. Replace reverse output gear, snap ring, reverse baulk

ring, return spring, needle

bearing, reverse idler shaft, spacer, reverse input gear, and lock washer as a

set, if necessary.

• Damage, peeling, bend, uneven wear, and distortion of shaft • Excessive wear, damage, and peeling of gear

Bearing

Check damage and rotation of bearing. Replace reverse output gear, snap ring,

reverse baulk ring, return

spring, needle bearing, reverse idler shaft, spacer, reverse input gear, and

lock washer as a set, if necessary.

Mainshaft and gear

Mainshaft and gear

Exploded View

1. Mainshaft front bearing outer

race

2. Mainshaft front bearing inner race

3. Mainshaft

4. 1st main gear

5. 1st inner baulk ring

6. 1st synchronizer cone

7. 1st outer baulk r ...

Final drive

Final drive

Exploded View

1. Shim

2. Differential side bearing outer race

(transaxle case side)

3. Differential side bearing inner race

(transaxle case side)

4. Final gear

5. Differential case

6. Dif ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

Engine does not start when intelligent key is inside of vehicle

Description

Engine does not start when push-button ignition switch is pressed while

carrying Intelligent Key.

NOTE:

• Check that vehicle is under the condition shown in “Conditions of vehicle”

before starting diagnosis, and

check each symptom.

• The engine start function, door lock functi ...

Key ID warning does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&qu ...