Nissan Juke Service and Repair Manual : Rear fog lamp circuit

Component Function Check

1.CHECK REAR FOG LAMP OPERATION

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “RR FOG LAMP” of BCM (HEAD LAMP) active test item.

2. With operating the test items, check that the rear fog lamp is turned ON.

On : Rear fog lamp ON Off : Rear fog lamp OFF

Is the inspection result normal? YES >> Rear fog lamp circuit is normal.

NO >> Refer to EXL-56, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK REAR FOG LAMP BULB

Check applicable lamp bulb.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace bulb.

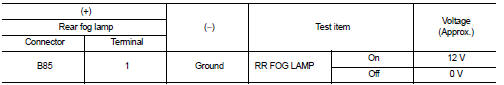

2.CHECK REAR FOG LAMP OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Turn ignition switch OFF.

2. Disconnect rear fog lamp connector.

3. Turn ignition switch ON.

4. Select “RR FOG LAMP” of BCM (HEAD LAMP) active test item.

5. With operating the test items, check voltage between rear fog lamp harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 3.

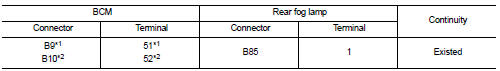

3.CHECK REAR FOG LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and rear fog lamp harness connector.

*1: Without Intelligent Key *2: With Intelligent Key

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

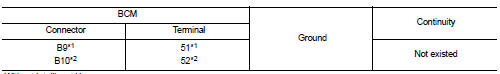

4.CHECK REAR FOG LAMP SHORT CIRCUIT

Check continuity between BCM harness connector and ground.

*1: Without Intelligent Key *2: With Intelligent Key

Is the inspection result normal? YES >> Check bulb socket for internal short circuit, and if check result is normal, replace BCM. Refer to BCS-93, "Removal and Installation" (with Intelligent Key), BCS-161, "Removal and Installation" (without Intelligent Key).

NO >> Repair or replace harness.

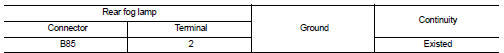

5.CHECK REAR FOG LAMP GROUND OPEN CIRCUIT

Check continuity between rear fog lamp harness connector and ground.

Is the inspection result normal? YES >> Check corresponding bulb socket and harness. Repair or replace if necessary.

NO >> Repair or replace harness.

Front fog lamp circuit

Front fog lamp circuit

Component Function Check

1.CHECK FRONT FOG LAMP OPERATION

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2. With operating the test items, check that the front fo ...

Parking lamp circuit

Parking lamp circuit

Without daytime running light system

WITHOUT DAYTIME RUNNING LIGHT SYSTEM : Component Function Check

1.CHECK PARKING LAMP OPERATION

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R a ...

Other materials:

Wiring diagram

EXTERIOR LIGHTING SYSTEM

Wiring Diagram

For connector terminal arrangemants, harness layouts, and alphabets in a

(option abbreviation: if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

Compression pressure

Inspection

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-551, "Work Procedure".

3. Remove ignition coil and spark plug from each cylinder. Refer to EM-178,

"Exploded View".

4. Connect engine tachometer (not required in use of CONSULT-III ...

Precaution

REPAIRING HIGH STRENGTH STEEL

High Strength Steel (HSS)

High strength steel is used for body panels in order to reduce vehicle

weight.

Accordingly, precautions in repairing automotive bodies made of high strength

steel are described below:

FOR 2WD MODELS

FOR 4WD MODELS

Read the follo ...