Nissan Juke Owners Manual : Push-button ignition switch operation

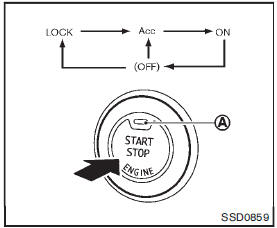

When the ignition switch is pushed without depressing the brake pedal (Continuously Variable Transmission models) or the clutch pedal (manual transmission models), the ignition switch position will change as follows: • Push once to change to ACC.

• Push two times to change to ON.

• Push three times to change to OFF.

• Push four times to return to ACC.

• Open or close any door to return to LOCK during the OFF position.

The indicator light A on the ignition switch illuminates when the ignition switch is in the ACC or ON position.

Some indicators and warnings for operation are displayed on the meter. (See “Warning/indicator lights and audible reminders” .) Continuously Variable Transmission models

The ignition lock is designed so that the ignition switch position cannot be switched to LOCK until the shift lever is moved to the P (Park) position.

When the ignition switch cannot be pushed toward the LOCK position, proceed as follows: 1. Move the shift lever into the P (Park) position.

2. Push the ignition switch to the OFF position.

3. Open the door. The ignition switch will change to the LOCK position.

The shift lever can be moved from the P (Park) position if the ignition switch is in the ON position and the brake pedal is depressed.

Operating range for engine start function

Operating range for engine start function

The Intelligent Key can only be used for starting the engine when the Intelligent

Key is within the specified operating range1 .

When the Intelligent Key battery is almost discharged or strong ra ...

Push-button ignition switch positions

Push-button ignition switch positions

LOCK (Normal parking position)

The ignition switch can only be locked in this position.

The ignition switch will be unlocked when it is pushed to the ACC position while

carrying the Intelligent Ke ...

Other materials:

Security indicator lamp does not turn on or blink

Description

Security indicator lamp does not blink when ignition switch is in a position

other than ON.

NOTE:

• Before performing the diagnosis, check “Work Flow”. Refer to SEC-187, "Work

Flow".

• Check that vehicle is under the condition shown in “CONDITIONS OF VEHICLE

(OPERAT ...

Fillet molding

Exploded View

1. Grommet

2. Clip

3. Clip

4. Front fillet molding

5. Rear fillet molding

: Pawl

: Do not reuse

Front fillet molding

FRONT FILLET MOLDING : Removal and Installation

REMOVAL

1. Remove front fillet molding fixing clips.

2. Remove front fillet molding front side fixing pa ...

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information. Check that any symptom

occurs other than the interviewed

symptom.

Insufficient cooling/heat ...