Nissan Juke Service and Repair Manual : Power supply and ground circuit

Diagnosis Procedure

1.INSPECTION START

Start engine.

Is engine running? YES >> GO TO 6.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION-I

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace ground connection.

3.CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

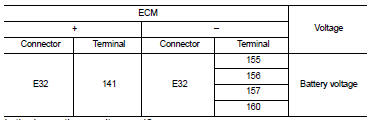

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M77, E105

• 10A fuse (No. 2)

• Harness for open or short between ECM and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

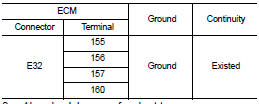

5.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

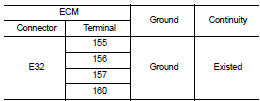

1. Disconnect ECM harness connectors.

2. Check the continuity between ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair open circuit or short to power in harness or connectors.

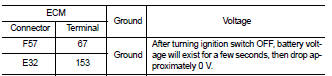

6.CHECK ECM POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 13.

NO-1 >> Battery voltage does not exist: GO TO 7.

NO-2 >> Battery voltage exists for more than a few seconds: GO TO 10.

7.CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 10.

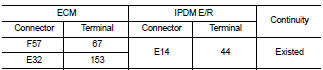

8.CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector.

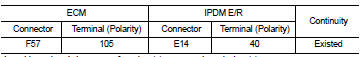

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 15.

NO >> GO TO 9.

9.DETECT MALFUNCTIONING PART

Check the following.

• Harness or connectors E8, F1 • Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

10.CHECK ECM POWER SUPPLY CIRCUIT-V

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 12.

NO >> GO TO 11.

11.DETECT MALFUNCTIONING PART

Check the following.

• Harness or connectors E8, F1 • Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK 20A FUSE

1. Disconnect 20A fuse (No. 43) from IPDM E/R.

2. Check 20A fuse.

Is the inspection result normal? YES >> GO TO 15.

NO >> Replace 20A fuse.

13.CHECK GROUND CONNECTION-II

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 14.

NO >> Repair or replace ground connection.

14.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect ECM harness connector.

2. Check the continuity between ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 15.

NO >> Repair open circuit or short power in harness or connectors.

15.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair open circuit or short to power in harness or connectors.

P0001 fuel pump

P0001 fuel pump

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0001 is displayed with DTC P0560 or P0657, first perform trouble

diagnosis for DTC P0560 or P0657.

Refer to EC-963, "DTC Logic" (DTC P05 ...

Other materials:

Engine control system symptoms

Symptom Table

SYSTEM — BASIC ENGINE CONTROL SYSTEM

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & OTHER

1 - 6: The numbers refer to the order of inspection ...

Rear-facing child restraint installation using the seat belts

WARNING

The three-point seat belt with Automatic Locking Retractor (ALR) must be used

when installing a child restraint.

Failure to use the ALR mode will result in the child restraint not being properly

secured. The restraint could tip over or be loose and cause injury to a child in

a sudd ...

ECU diagnosis information

4WD control module

Reference Value

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

*: The values are changed by throttle opening and engine speed.

CAUTION:

When using circuit tester to measure voltage for inspection, be sure not to

extend forcibly any connector

t ...