Nissan Juke Service and Repair Manual : P17B7 high clutch solenoid

DTC Logic

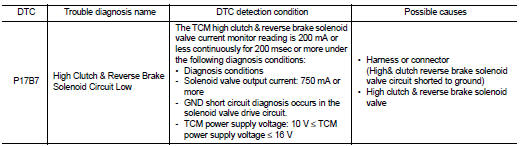

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine and wait for 5 seconds or more.

2. Check the first trip DTC.

Is “P17B7” detected? YES >> Go to TM-453, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

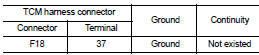

1.CHECK CIRCUIT BETWEEN TCM AND THE CVT UNIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and the CVT unit connector.

3. Check the continuity between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check the high clutch & reverse brake solenoid valve. Refer to TM-454, "Component Inspection (High Clutch & Reverse Brake Solenoid Valve)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

Component Inspection (High Clutch & Reverse Brake Solenoid Valve)

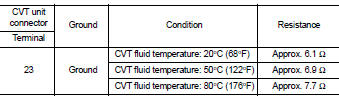

1.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check the resistance between the CVT unit connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of the high & reverse brake solenoid valve. Replace the transaxle assembly.

Refer to TM-508, "Removal and Installation".

Component Inspection (Low Brake Solenoid Valve)

Component Inspection (Low Brake Solenoid Valve)

1.CHECK LOW BRAKE SOLENOID VALVE

Check the resistance between the CVT unit connector terminal and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> There is a malf ...

P17B8 high clutch solenoid

P17B8 high clutch solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Other materials:

System initialization

Description

If any of the following operations are performed, the initialization is

necessary for normal operation of power

window system.

• Disconnection and connection of battery cable from negative terminal.

• When power window main switch replaced.

• Electric power supply to power windo ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...

Component parts

CVT control system : Component Parts Location

1. Multi display unit (MDU)*

Refer to DMS-3, "Component Parts

Location".

2. Combination meter 3. Manual mode indicator

(On the combination meter)

4. Shift position indicator

(On the combination meter)

5. Malfunction indicator lamp (MI ...