Nissan Juke Service and Repair Manual : P1778 step motor

Description

• The step motor's 4 aspects of ON/OFF change according to the signal from TCM. As a result, the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

• This diagnosis item is detected when electrical system is OK, but mechanical system is NG.

• This diagnosis item is detected when the state of the changing the speed mechanism in unit does not operate normally.

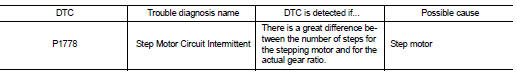

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

• Always drive vehicle at a safe speed.

• Before starting “DTC CONFIRMATION PROCEDURE”, confirm “Hi” or “Mid” or “Low” fixation by “PRI SPEED” and “VEHICLE SPEED” on “DATA MONITOR MODE”.

• If hi-geared fixation occurred, go to TM-252, "Diagnosis Procedure".

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “Self Diagnostic Results” in “TRANSMISSION”.

3. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN : 1.0 – 2.0 V If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to increase the voltage (cool down the fluid)

4. Start engine and maintain the following conditions for at least 30 consecutive seconds.

TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION : Keep 30 seconds or more

VEHICLE SPEED : 10 km/h (6 MPH) or more

ACC PEDAL OPEN : More than 1.0/8

RANGE : “D” position

ENG SPEED : 450 rpm or more

With GST.

With GST.

Follow the procedure “With CONSULT-III”.

Is “P1778” detected? YES >> Go to TM-252, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

1.CHECK STEP MOTOR

With CONSULT-III

With CONSULT-III

It is monitoring whether “GEAR RATIO: 2.34 – 0.39” changes similarly to “STM STEP: 0 – 177” by “DATA MONITOR” mode.

Without CONSULT-III

Without CONSULT-III

Inspect the engine speed (rise and descend), vehicle speed, throttle position, and check shift change. Refer to TM-308, "Shift Characteristics".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the transaxle assembly. Refer to TM-301, "Removal and Installation".

P1777 step motor

P1777 step motor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignit ...

Shift position indicator circuit

Shift position indicator circuit

Description

• TCM sends position indicator signals to combination meter by CAN

communication line.

• Manual mode switch position is indicated on shift position indicator

Component Function Check

...

Other materials:

System

WITH AUTO A/C

WITH AUTO A/C : System Diagram

WITH AUTO A/C : System Description

OPERATION DESCRIPTION

• BCM detects that the rear window defogger switch turns ON when the ignition

switch is ON, and then transmits

the rear window defogger switch signal to IPDM E/R via CAN communication for

...

Main line between DLC and A-bag circuit

Diagnosis Procedure

1.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the BCM harness connector.

4. Check the continuity between the data link connector and the BCM harness

connector.

- With In ...

Sun visors

TILT OPERATION

Push the lock lever down 1 and adjust the steering wheel up or down 2 to the

desired position.

Pull the lock lever up 3 securely to lock the steering wheel in place.

1. To block out glare from the front, swing down the sun visor1 .

2. To block glare from the side, remove the ...