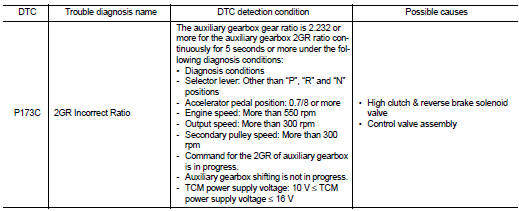

Nissan Juke Service and Repair Manual : P173C 2GR incorrect ratio

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

• Be sure to perform “TM-447, "Diagnosis Procedure"” and then perform “DTC

CONFIRMATION PROCEDURE”.

• Never perform "DTC CONFIRMATION PROCEDURE" before the repairs. Doing so may result in a secondary malfunction.

• Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 10 seconds or more.

Selector lever : “D” POSITION Accelerator pedal position : 0.7/8 or more Vehicle speed : 45 km/h (28 MPH) or more

4. Stop the vehicle.

5. Check the first trip DTC.

Is “P173C” detected? YES >> Go to TM-447, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace the transaxle assembly. Refer to TM-508, "Removal and Installation".

NO >> Repair or replace the malfunctioning parts.

P173B 1GR incorrect ratio

P173B 1GR incorrect ratio

DTC Logic

DTC CONFIRMATION PROCEDURE

CAUTION:

• Be sure to perform “TM-445, "Diagnosis Procedure"” and then perform “DTC

CONFIRMATION PROCEDURE”.

• Never perform "DTC CONFIRMATION ...

P17B4 low brake solenoid

P17B4 low brake solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Other materials:

Key warning lamp

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “INDICATOR” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Key warning lamp ...

Camshaft valve clearance

Inspection and Adjustment

INSPECTION

Perform inspection as follows after removal, installation or replacement of

camshaft or valve-related parts, or if

there is unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to EM-178, "Removal and Installation".

...

Removal and Installation

CAUTION:

• Be sure to use genuine exhaust system parts or equivalents which are specially

designed for heat

resistance, corrosion resistance and shape.

• Perform the operation with the exhaust system fully cooled down because the

system is still hot just

after the engine stops.

• Be careful ...