Nissan Juke Service and Repair Manual : P1643 thermoplunger control unit

DTC Logic

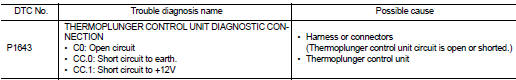

DTC DETECTION LOGIC

Diagnosis Procedure

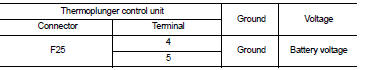

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector.

3. Check the voltage between thermoplunger control unit harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

• 100A fusible link (letter B) • Harness for open and short between thermoplunger control unit and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

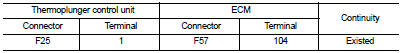

3.CHECK THERMOPLUNGER CONTROL UNIT GROUND CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check the continuity between thermoplunger control unit harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

Is the inspection result normal? YES >> Replace thermoplunger control unit.

NO >> Repair or replace.

P1642 thermoplunger control unit

P1642 thermoplunger control unit

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector ...

P1650 thermoplunger control unit

P1650 thermoplunger control unit

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector ...

Other materials:

A-bag branch line circuit

Diagnosis Procedure

WARNING:

• Before servicing, turn ignition switch OFF, disconnect battery negative

terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disco ...

Operation inspection

Work Procedure

The purpose of the operational check is to check that the individual system

operates normally.

Check condition : Engine running at normal operating temperature.

1.CHECK MEMORY FUNCTION

1. Set temperature to 30°C by operating the temperature control dial.

2. Press OFF switch.

3 ...

Fuel pressure control

Fuel pressure control : System Diagram

Fuel pressure controlL : System Description

INPUT/OUTPUT SIGNAL CHART

*: ECM determines the start signal status by the engine speed signal and

battery voltage.

CVT models

System Description

Low fuel pressure control

• The low fuel pressure pump i ...