Nissan Juke Service and Repair Manual : P0715 input speed sensor A

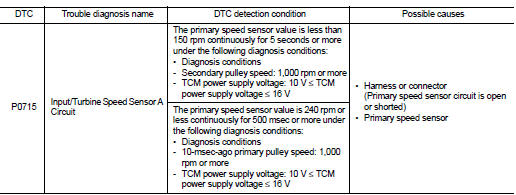

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 10 seconds or more.

Selector lever : “L” POSITION Vehicle speed : 40 km/h (25 MPH) or more

4. Stop the vehicle.

5. Check the first trip DTC.

Is “P0715” detected? YES >> Go to TM-410, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

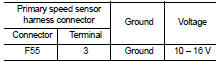

1.CHECK PRIMARY SPEED SENSOR POWER CIRCUIT

Check voltage between primary speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 6.

NO >> GO TO 2.

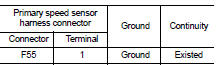

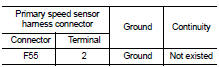

2.CHECK PRIMARY SPEED SENSOR GROUND CIRCUIT

Check continuity between primary speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

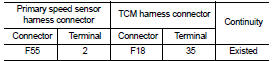

3.CHECK CIRCUIT BETWEEN PRIMARY SPEED SENSOR AND TCM (PART 1)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check continuity between primary speed sensor harness connector terminal and TCM harness connector terminal.

Is the check result normal? YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CHECK CIRCUIT BETWEEN PRIMARY SPEED SENSOR AND TCM (PART 1)

Check continuity between primary speed sensor harness connector terminal and ground.

YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

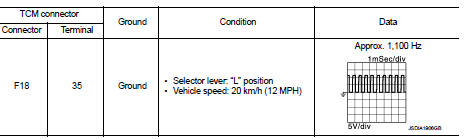

5.CHECK TCM INPUT SIGNALS

1. Connect all of the disconnected connectors.

2. Lift the vehicle.

3. Start the engine.

4. Check frequency of primary speed sensor.

Is the check result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the primary speed sensor. TM-495, "Removal and Installation".

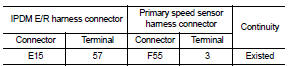

6.CHECK CIRCUIT BETWEEN IPDM E/R AND PRIMARY SPEED SENSOR (PART 1)

1. Disconnect the IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector terminal and primary speed sensor harness connector terminal.

Is the check result normal? YES >> GO TO 7.

NO >> Repair or replace the malfunctioning parts.

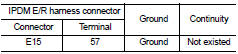

7.CHECK CIRCUIT BETWEEN IPDM E/R AND PRIMARY SPEED SENSOR (PART 2)

Check continuity between IPDM E/R harness connector terminal and ground.

Is the check result normal? YES >> GO TO 8.

NO >> Repair or replace the malfunctioning parts.

8.DETECTION OF MALFUNCTION ITEMS

Check the following items: • Harness open circuit or short circuit between the ignition switch and IPDM E/R. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

• 10A fuse (No.55, IPDM E/R). Refer to PG-25, "Fuse, Connector and Terminal Arrangement".

• IPDM E/R Is the check result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

P0713 transmission fluid temperature sensor A

P0713 transmission fluid temperature sensor A

DTC Logic

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, th ...

P0720 output speed sensor

P0720 output speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just befor ...

Other materials:

Wiring diagram

BCM

LHD

LHD : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

RHD

RHD : Wiring Diagram

For con ...

Hazard function

Component Function Check

1.CHECK FUNCTION

1. Select “MULTI REMOTE ENT” of “BCM” using CONSULT-III.

2. Select “FLASHER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Hazard warning lam ...

Rear door

Exploded View

1. Rear door panel

2. Door hinge (upper)

3. Door hinge (lower)

4. Door check link

5. Door striker

6. TORX bolt

: Do not reuse

: N·m (kg-m, in-lb)

N·m (kg-m, ft-lb)

: Body grease

Door assembly

DOOR ASSEMBLY : Removal and Installation

CAUTION:

• Perform work with 2 w ...