Nissan Juke Service and Repair Manual : P0643 sensor power supply

DTC Logic

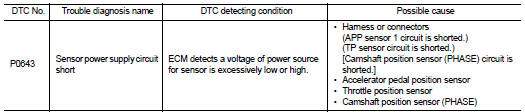

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to EC-686, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

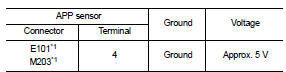

2.CHECK ACCELERATOR PEDAL POSITION SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between APP sensor harness connector and ground.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 3.

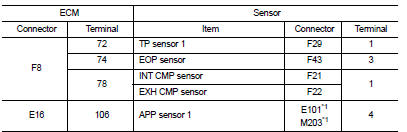

3.CHECK SENSOR POWER SUPPLY CIRCUIT

Check harness for short to power and short to ground, between the following terminals.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair short to ground or short to power in harness or connectors.

4.CHECK CAMSHAFT POSITION SENSOR (PHASE)

Refer to EC-662, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace camshaft position sensor (PHASE).

5.CHECK THROTTLE POSITION SENSOR

Refer to EC-646, "Component Inspection".

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 6.

6.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

Replace electric throttle control actuator. Refer to EM-163, "Exploded View".

>> INSPECTION END

7.CHECK APP SENSOR

Refer to EC-749, "Component Inspection".

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 8.

8.REPLACE ACCELERATOR PEDAL ASSEMBLY

Replace accelerator pedal assembly. Refer to ACC-3, "Exploded View".

>> INSPECTION END

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

P0607 ECM

P0607 ECM

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check DTC.

Is DTC detected?

YES >> Proceed to EC-685, &quo ...

P0850 PNP switch

P0850 PNP switch

Description

When the selector lever position is P or N (CVT), Neutral position (M/T),

park/neutral position (PNP) signal is

ON.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.INS ...

Other materials:

Back door window glass

Exploded View

1. Back door window glass

2. Spacer

3. Back door window glass holder

4. Back door window glass molding

5. Pivot seal

6. Adhesive

7. Primer

8. Back door outer

9. Back door inner

Unit: mm (in)

: Do not reuse

Removal and Installation

REMOVAL

1. Remove back door lower ...

Rear drive shaft

Exploded View

1. Circular clip

2. Dust shield

3. Housing

4. Snap ring

5. Ball cage/steel ball/inner race assembly

6. Stopper ring

7. Boot band

8. Boot

9. Shaft

10. Joint sub-assembly

11. Sensor rotor

: Wheel side

: Fill NISSAN genuine grease or an

equivalent.

: Always replace ...

P1651 starter motor relay

Description

ECM controls ON/OFF state of the starter relay, according to the engine and

vehicle condition. Models with no

Intelligent Key System transmit a control signal directly to IPDM E/R. On the

other hand, models with the Intelligent

Key System transmit a control signal to IPDM E/R by w ...