Nissan Juke Service and Repair Manual : P0197, P0198 EOT sensor

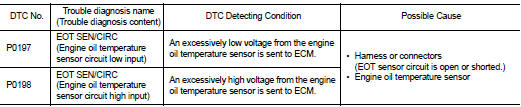

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-643, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

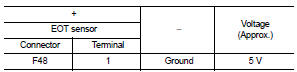

1.CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect engine oil temperature (EOT) sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between EOT sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

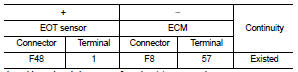

2.CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOT sensor harness connector and ECM harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

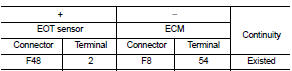

3.CHECK EOT SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOT sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE OIL TEMPERATURE SENSOR

Check the engine oil temperature sensor. Refer to EC-644, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace engine oil temperature sensor. Refer to EM-222, "Exploded View".

Component Inspection

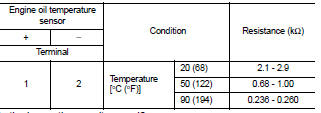

1.CHECK ENGINE OIL TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect engine oil temperature sensor harness connector.

3. Remove engine oil temperature sensor.

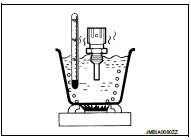

4. Check resistance between engine oil temperature sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace engine oil temperature sensor. Refer to EM-103, "Exploded View".

P0172 fuel injection system function

P0172 fuel injection system function

DTC Logic

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture

ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio fe ...

P0222, P0223 TP sensor

P0222, P0223 TP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0222 or P0223 is displayed with DTC P0643, first perform the trouble

diagnosis for DTC P0643.

Refer to EC-686, "DTC Logic".

DTC CONFIRM ...

Other materials:

P0641 sensor power supply

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or r ...

Oil pan

Exploded View

1. Transaxle assembly

2. Oil pan gasket

3. Magnet

4. Oil pan

5. Overflow tube

6. Drain plug gasket

7. Drain plug

8. Oil pan fitting bolt

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, it-lb)

Removal and Installation

REMOVAL

1. Remove t ...

Engine oil and oil filter recommendation

1. API certification mark

2. API service symbol

Selecting the correct oil

It is essential to choose the correct grade, quality, and viscosity engine oil

to ensure satisfactory engine life and performance, see “Capacities and recommended

fuel/lubricants” . NISSAN recommends the use of an ene ...