Nissan Juke Service and Repair Manual : P0132 A/F sensor 1

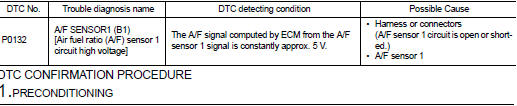

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed by ECM from the A/F sensor 1 signal is not inordinately high.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10.5 V at idle.

>> GO TO 2.

2.CHECK A/F SENSOR FUNCTION

With CONSULT-III

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “A/F SEN1 (B1)” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Check “A/F SEN1 (B1)” indication.

With GST

With GST

Follow the procedure “With CONSULT-III” above.

Is the indication constantly approx. 5 V? YES >> Proceed to EC-213, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

With CONSULT-III

1. Turn ignition switch OFF, wait at least 10 seconds and then restart engine.

2. Drive and accelerate vehicle to more than 40 km/h (25 MPH) within 20 seconds after restarting engine.

CAUTION:

Always drive vehicle at a safe speed.

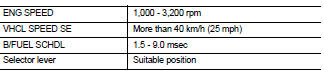

3. Maintain the following conditions for about 20 consecutive seconds.

NOTE:

• Keep the accelerator pedal as steady as possible during the cruising.

• If this procedure is not completed within 1 minute after restarting engine at step 1, return to step 1.

4. Check 1st trip DTC.

With GST

With GST

Follow the procedure “With CONSULT-III” above.

Is 1st trip DTC is detected? YES >> Proceed to EC-213, "Diagnosis Procedure".

NO >> INSPECTION END

Component Inspection

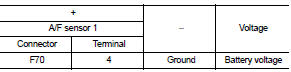

1.CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect A/F sensor 1 harness connector.

3. Turn ignition switch ON.

4. Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

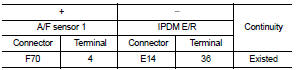

2.CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between A/F sensor 1 harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

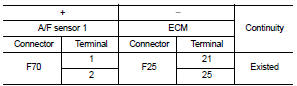

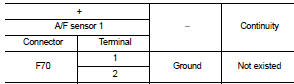

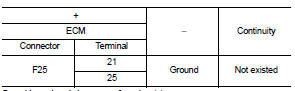

3.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector and ground.

5. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK INTERMITTENT INCIDENT

Perform GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1. Refer to EM-38, "Exploded View".

CAUTION:

• Discard any sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard

surface such as a concrete floor; use a new one.

• Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (J-43897-18 or J43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>> INSPECTION END

P0131 A/F sensor 1

P0131 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal is not inordinately low.

DTC CONFIRMATION PROCEDUR ...

P0133 A/F sensor 1

P0133 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction of A/F sensor 1, this diagnosis measures response

time of the A/F signal computed

by ECM from the A/F sensor 1 signal. The time is compensat ...

Other materials:

Unit removal and installation

Engine assembly

Exploded View

1. Engine mounting assembly (RH)

2. Rear engine mounting bracket

3. Rear torque rod

4. Engine mounting bracket (LH)

5. Stud bolt

6. Engine mounting bracket (LH)

7. Engine mounting insulator (LH)

8. Mass damper

: N·m (kg-m, ft-lb)

CAUTION:

Check that ...

Camshaft valve clearance

Inspection and Adjustment

INSPECTION

Perform inspection as follows after removal, installation or replacement of

camshaft or valve-related parts, or if

there is unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to EM-53, "Exploded View".

2. Measure ...

B1080, B1096 driver air bag module

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...